Laser Cut Gold/Copper 35Au-65Cu Service

Trusted by

1,000’s

of Satisfied Customers

30+

Years in Business

Gold–copper alloy in the 35Au–65Cu range is more than just a decorative “rose gold” metal. It is a material with deep historical roots and modern technical relevance. Used by pre-Columbian cultures for gilded artifacts and later refined into luxury watch cases, precision connectors, and high reliability brazing alloys, it combines with the strength and durability needed for fine components. Today, using laser cutting technology, flat precision parts from this alloy are produced with a balance of edge quality and tolerance control for scaled parts that are challenging for other manufacturing methods. Clearly, gold/copper alloy has a lot more to offer than meets the eye. To highlight its most practical aspects, here are some frequently asked questions and answers that shed light on this remarkable material.

How Does Laser Cutting Compare to Die-cutting, Waterjet, or CNC Machining of Gold/Copper Alloy?

Producing precision parts can be done in numerous ways and each method of manufacturing has applications and materials that they excel at. However, there is crossover between different technologies and choosing the best for your project is determined by the factors involved.

| Method | Precision & Tolerance | Edge Quality | Best For | Limitations |

|---|---|---|---|---|

| Laser Cutting | Holds very tight tolerances and is ideal for fine features. | Smooth clean edges with minimal HAZ. | Thin foils, intricate designs, prototyping, but can ramp up for volume production. | Limited on material thickness capacity vs CNC and waterjet. |

| Die-Cutting | Moderate precision. Tooling limits design details | Good on simple shapes, but less clean for more complex parts. | High volume of simple designs. | Tooling costs can be high and not flexible for design changes. |

| Waterjet Cutting | Very accurate for thicker stock materials. | Good edge quality with no thermal stress. | Cutting thicker sheets and plate without HAZ. | Slower for finer features, not good for materials prone to liquid absorption and abrasive damage. |

| CNC Machining | Can achieve high accuracy. | Clean, but may require post finishing. | Great for 3D parts for custom geometries. | Will need to be slower for thinner stocks. Material waste can be higher. |

The table is for general considerations of capabilities but does not define manufacturing methods full functions and ability to process materials.

What Are the Tightest Tolerances Your Laser Cutting Process Can Maintain When Cutting Gold/Copper 35Au-65Cu?

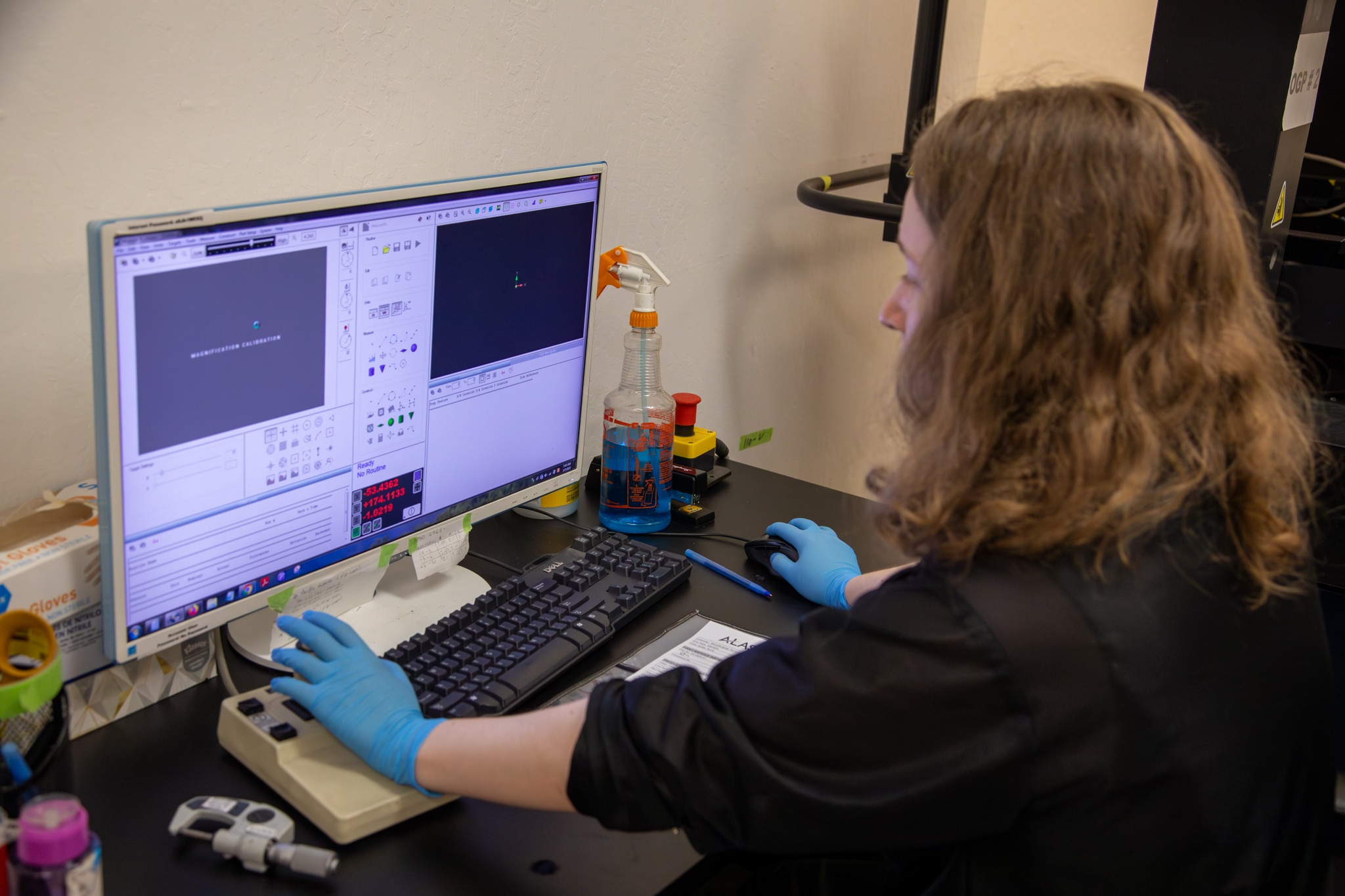

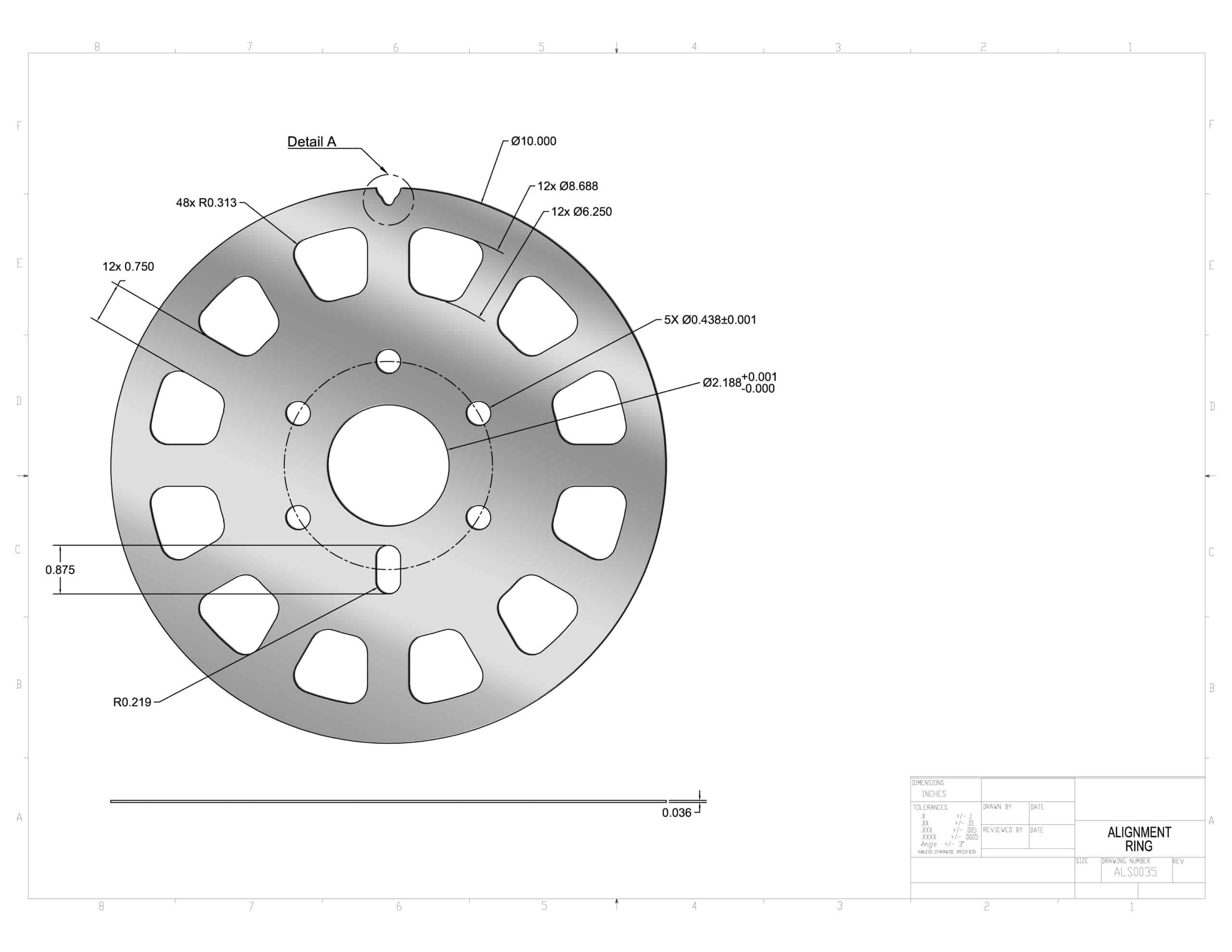

Using ultraviolet or femtosecond lasers to cut Gold/Copper alloy will result in very tight tolerance control. For ultraviolet lasers, you will see typically a +/- 0.5 mils to 1mil. With femtosecond lasers a tolerance of +/- of 0.5mils will be achieved. Both system types have narrow kerfs that enable microfeatures to be produced. Gold/Copper 35Au–65Cu is a technically challenging alloy to cut with precision, but by using advanced UV and femtosecond lasers, those hurdles are turned into advantages.

How Do Material Characteristics Like Reflectivity, Softness, or Thermal Conductivity Affect Edge Quality and Tolerance Control in Gold/Copper?

Material characteristics like thermal conductivity, softness, and reflectivity can significantly impact edge quality and tolerance control in laser cutting gold/copper 35Au-65Cu alloys. These properties influence how the material interacts with the laser cutting so adjustments are needed.

Thermal Conductivity

- Improved Edge Quality: Rapid heat dissipation prevents the workpiece from overheating, which greatly helps maintain a cleaner, more defined edge.

- Better Tolerance Control: Thermal expansion is minimized, by controlling laser parameters of cut speed, power and laser passes. More precise dimensional control and tighter tolerances are crucial for high-precision components like those used in electronics or aerospace.

Softness and Ductility

- Edge Quality Issues: The softness can cause edge quality concerns, so adjustment of the laser parameters, as mentioned, reduce burrs and slag.

Reflectivity

- Laser Machining Challenges: Highly reflective materials like gold/copper alloys are more challenging to laser cut because a portion of the light energy is not being absorbed by the material. If adjustments to the laser power, wavelength, focus and other factors, are not done potentially this will lead to incomplete cuts, and poor feature definition.

The alloy’s natural softness helps create smooth, clean edges, while the right laser control ensures parts stay accurate down to the micron. The result is precision components that combine the elegance of gold with the reliability of high-tech manufacturing.

What Edge Quality Can Be Expected When Laser Cutting Gold/Copper 35Au-65Cu? Are Burrs or Heat-Affected Zones (HAZ) Present?

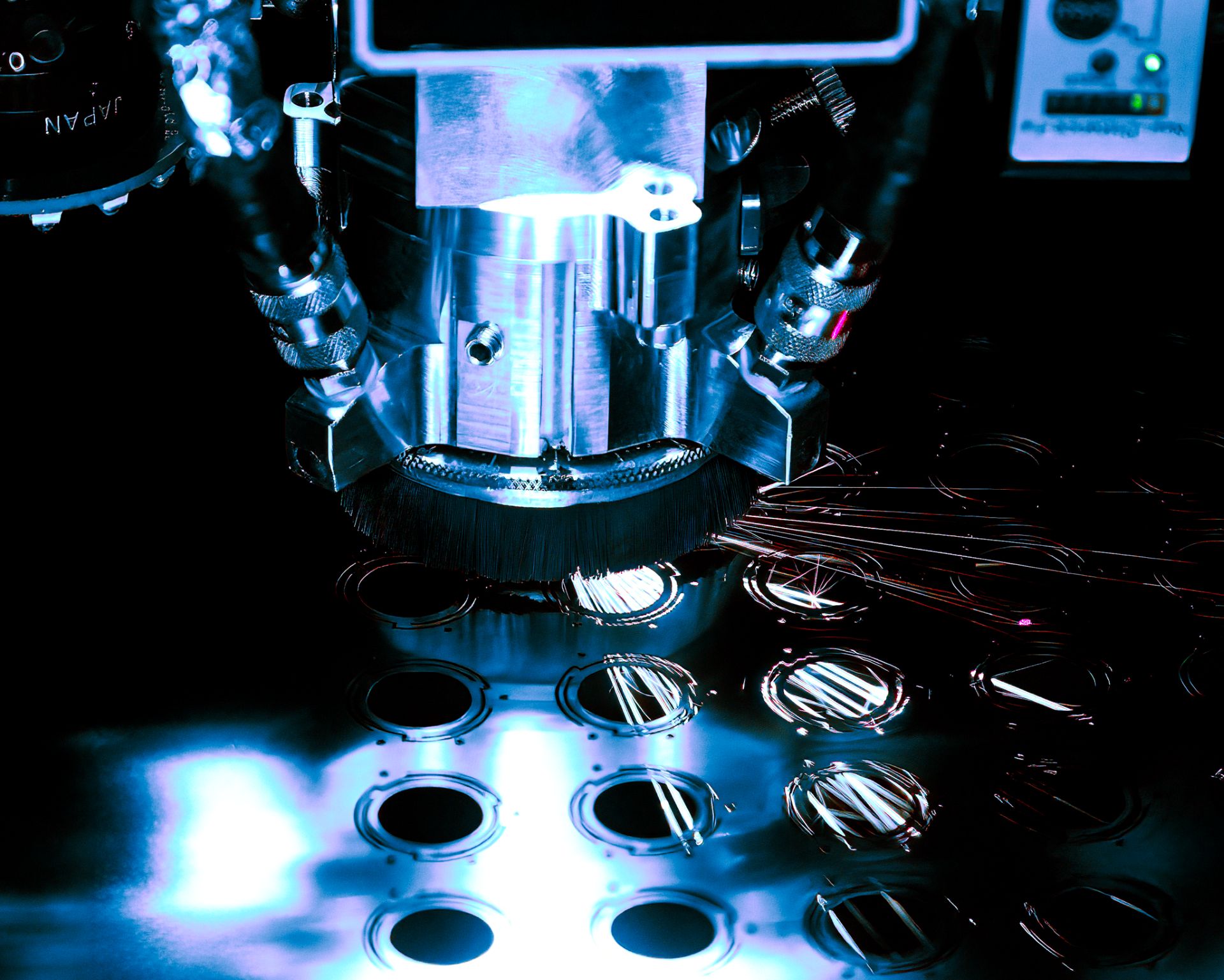

When laser cutting Gold/Copper 35Au-65Cu, you can expect high-edge quality with minimal burr formation, but the process must be carefully controlled due to the alloy’s properties. Burrs are generally minimal, as the laser vaporizes the material with a focused beam, but dross or small burrs can still appear on the bottom of the cut if settings are not optimized.

The presence of a Heat-Affected Zone (HAZ) is a significant consideration. While laser cutting is a thermal process that introduces heat, the HAZ for Gold/Copper 35Au-65Cu is typically small and localized.

What Are the Benefits of Laser Cutting Gold/Copper Alloy?

The non-contact nature of laser cutting and the ability to automate production also provide a competitive edge. Laser cutting has other key advantages to cutting Gold/Copper alloy and one of them is the ability to cut thin metal foils. Gold/Copper alloy can be easily damaged before processing, so experience in handling and processing is a key factor. Lasers do this without incurring any mechanical stress to these delicate and costly foils. Another great advantage is the superior edge quality that will be achieved. Lasers have small beam diameters that when used within the accuracy of the technology produce identical parts. Not to be forgotten but materials are costly and keeping waste down by efficient nesting, is a big plus for laser use. These advantages are crucial when working with high-value materials like gold/copper alloys.

Bringing It All Together

Gold/Copper alloys may not be the most common materials being used in technology, but they are crucial for the applications they are designed to support. These delicate foils are too thin for mechanical methods to process and therefore laser technology has proven to be the go-to way to manufacture precision components for intricate braze preforms for aerospace, electronics, medical devices and nuclear engineering. With characteristics of high strength and resistance to oxidation and corrosion at elevated temperatures, the alloy itself is not typically laser cut for final products in the way a sheet of steel would be. Laser cutting technology is crucial for producing precise preforms with high edge quality and tight tolerances that are necessary for critical use applications.