Laser Cut Elgiloy Service

Trusted by

1,000’s

of Satisfied Customers

30+

Years in Business

Elgiloy® is a registered trademark of Elgiloy Specialty Metals and is also known under the trade name Phynox. It is a cobalt-chromium-nickel-molybdenum alloy that’s non-magnetic, highly corrosion-resistant, and famous for its strength and fatigue life. Manufacturing precision parts out of Elgiloy can be challenging as it hardens quickly and dulls cutting tools. Mechanical processes can have trouble in creating small intricate features and tight radii. Laser cutting on the other hand is non-contact so you can make delicate, repeatable features out of Elgiloy. For additional information about laser technology and processing of Elgiloy material, the following questions and answers are provided.

Factoring Characteristics

How Do Material Characteristics Like Reflectivity, Softness, or Thermal Conductivity Affect Edge Quality and Tolerance Control in Elgiloy?

Elgiloy might look like just another shiny strip of metal, but the way it behaves under a laser is anything but ordinary. Its reflective surface can try to ‘bounce back’ laser energy and its spring-like characteristic makes it want to flex instead of sitting still. Traits like this can dictate how smooth the edges turn out and how tightly we can hold a precision tolerance specification. With the right laser parameters, however, these challenges are overcome. In short, the very quirks that make Elgiloy tricky are also what make laser cutting the perfect partner for shaping it into precision parts.

| Trait | How It Challenges Cutting | How Laser Technology Adjusts |

|---|---|---|

| Reflectivity | Bounces laser energy away, risking inconsistent cuts. | Short-pulse and UV/fiber lasers deliver energy faster than it can reflect, ensuring clean edges. |

| Softness & Elasticity | Material wants to flex, causing distortion or uneven tolerances. | Materials are held via vacuum, thus avoiding tool pressure or movement. |

| Thermal Conductivity | Spreads heat out, enlarging heat-affected zones (HAZ). | Ultrafast pulses localize heat, keep edges sharp, minimize HAZ and reduce finishing needs. |

Measuring Up

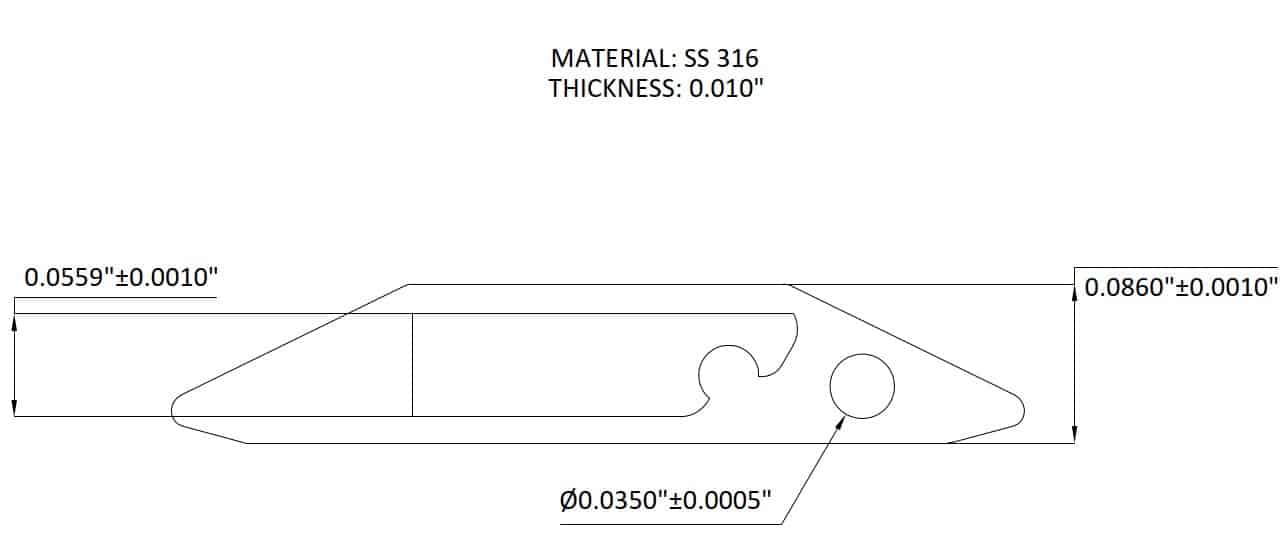

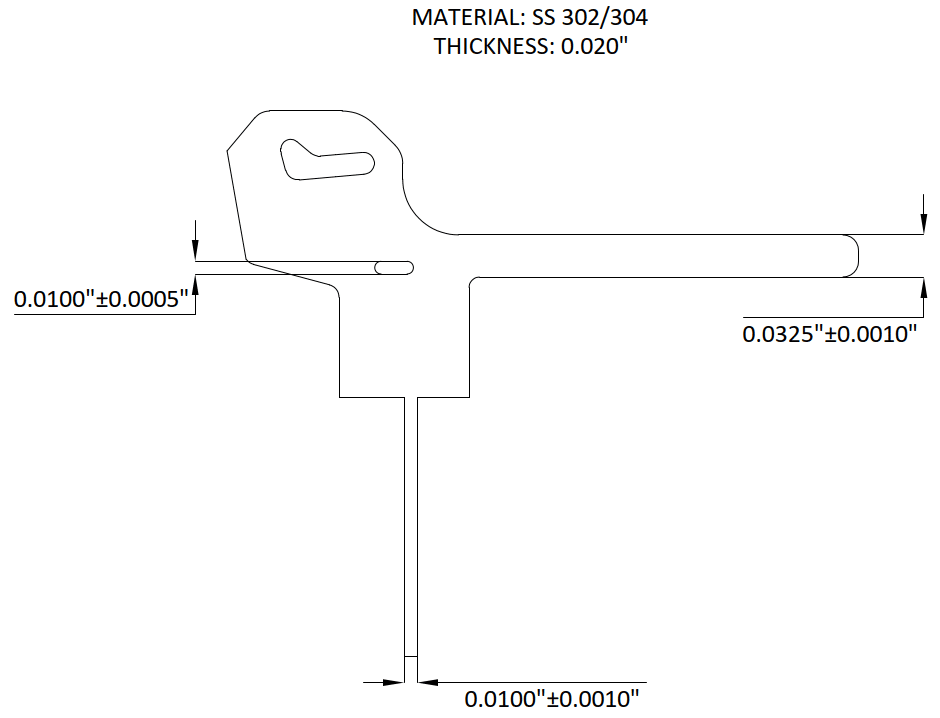

What Are the Tightest Tolerances Your Laser Cutting Process Can Maintain When Cutting Elgiloy?

Laser cutting makes it possible to sculpt Elgiloy with tolerances measured in mere thousandths of an inch. Think of it this way: if you placed a human hair next to one of our laser-cut features, the gap would be just a fraction of that thickness. That level of control is what lets Elgiloy go from a challenging alloy into flawless springs, clips, or implant components that fit together precisely as designed. The solution is not just using a laser beam, rather it’s in carefully tuned parameters that keep heat, reflection, and material stress in check. The result are crisp edges, repeatable dimensions, and tolerances that consistently hold tight, even on a metal designed to push back.

| Tolerance Level | What It’s Like | Application |

|---|---|---|

| +/- .5 mil | About 1/4 the width of a human hair. | Ultra-precision parts, like medical implants, electronics. |

| +/- 1mil | Roughly the thickness of a sheet of paper. | Common specification for springs, clips, and aerospace parts. |

| +/- 2mil | About the diameter of a fine grain of sand. | Extremely precise for many industrial uses. |

Controlling Edge Quality

What Edge Quality Can Be Expected When Laser Cutting Elgiloy? Are Burrs or Heat-Affected Zones (HAZ) Present?

Cutting Elgiloy can be like carving into armor, which is tough, springy, and resilient. With modern laser technology, the results are surprisingly clean. The beam leaves behind edges that are smooth enough to flex without cracking, sharp enough to mate perfectly with other components, and consistent from part to part. Yes, Elgiloy can develop a heat-affected zone if you use it too much energy. With ultrafast or finely tuned fiber lasers, that zone shrinks dramatically. They’re minimal to no burrs and often eliminated entirely with the right pulse settings. This reduces heavy postprocessing and may only require light sanding.

Manufacturers Compete

How Does Laser Cutting Compare to Die-cutting, Waterjet, or CNC Machining of Elgiloy?

Trying to cut sheets of Elgiloy with traditional tools is like using a kitchen knife to cut through diamonds. Die-cutting can struggle and wear out fast, waterjets use high water pressure and abrasive media to cut their way through but leave rough edges, and CNC tools can deform or tear thin sheets and foils so can be challenging for use. Lasers, on the other hand, laser cutters are made to cut metal foils and thin sheets. They don’t push or grind, but use light energy to cut through. The focused beam ablates through Elgiloy without physical contact, creating crisp geometries that are superior to stamping and do not wear bits as used in CNC Milling.

For Elgiloy, laser cutting may be the better option that unlocks shapes and tolerances the other methods simply can’t reach, but it is not the final solution. Each project will need to have the details reviewed and determined which manufacturing technology is best overall in producing a high-quality component that fits withing the cost and needed throughput.

Laser Advantages

What Are the Benefits of Laser Cutting Elgiloy?

Laser cutting can be a great solution for flat components made of Elgiloy material. For supporting industries that require high edge quality and repeatable precision, laser cutting services continue to be a part of the supply chain of advancing industries. A quick view of these benefits are:

- Cuts the “uncuttable” — Elgiloy can be challenging to saws and dulls drills, but a laser slices through it like light through glass.

- Edges that shine — crisp, burr-free profiles.

- Shapes that twist the imagination — delicate springs, flexures, and micro-features that stamping or machining simply can’t touch.

- Tolerances tighter than a secret handshake — repeatable precision down to fractions of a human hair.

- No tool wear drama — because there’s no tool, just a beam of light, you get consistency from the first part to the thousandth.

- From aerospace to the human body — the edge quality is clean enough for aircraft components and biocompatible implants.

Conclusion

Elgiloy’s story begins with a stubborn watch spring alloy to a material trusted in aircraft, energy systems, medical device use and many other high precision applications. Its use of course has not stopped there but grown in part with laser cutting technology creating more opportunities. With light as the tool, engineers can now unlock Elgiloy’s full potential, shaping it into parts that are as intricate as they are durable. However, as a reminder that in materials science, there are numerous ways to solve problems and succeed or sometimes fail in the pursuit. Manufacturing components out of Elgiloy can be challenging for any manufacturing method. Learning through communication with qualified service providers is the best approach to focusing support for your next project.