Laser Cutting Double Side Graphite Coated Paper Service

Trusted by

1,000’s

of Satisfied Customers

30+

Years in Business

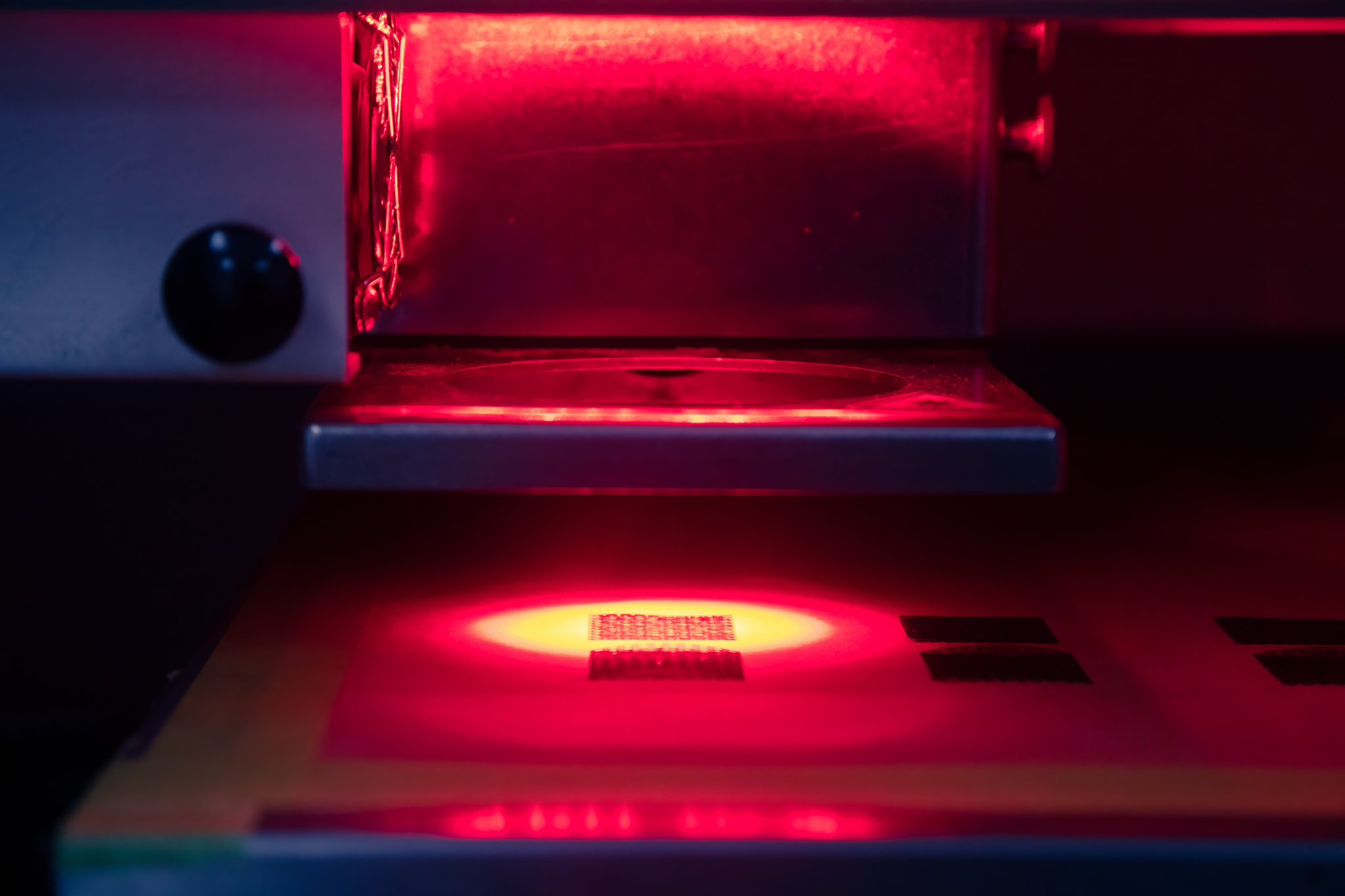

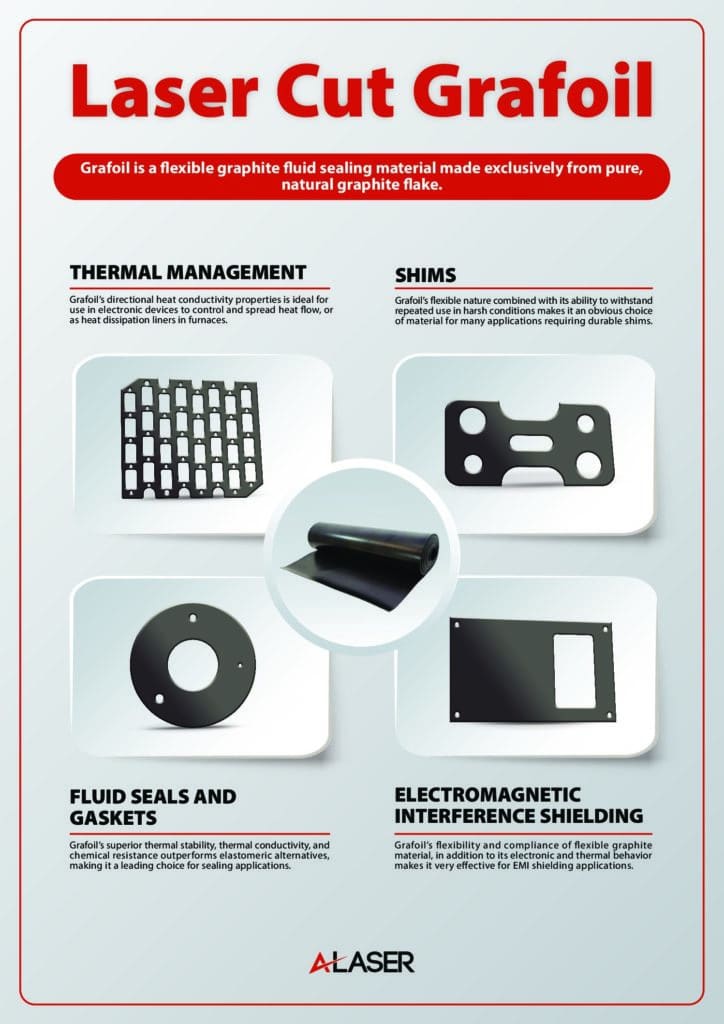

One of the most exciting aspects of laser cutting services is the wide variety of materials we can work with. Innovative ideas and designs go together with inventive uses for these materials. For instance, double-sided graphite coated paper, which is sometimes called flexible graphite foil or sheet, is an exceptional choice. With laser cutting, we tap into its full potential for applications that require outstanding thermal, electrical, and sealing properties.

This material excels in extreme settings, whether it’s used for high-temperature gaskets in the petrochemical industry or as part of advanced thermal management and current collection systems in modern electronics and high-capacity batteries. To take advantage of its unique features without damaging its delicate structure, precise technology is essential. Our state-of-the-art laser cutting services are designed to shape this fragile, high-performance material into custom components with micrometer-level accuracy, ensuring complex, clean shapes for your critical systems.

Explore our Q&A section to learn how we expertly cut flexible graphite to address your toughest engineering needs.

What Are the Tightest Tolerances Your Laser Cutting Process Can Maintain When Cutting Double-Sided Graphite Coated Paper?

Industries require precision and tolerance control, especially for applications that impact safety. Precision can be seen as hitting the mark consistently and tolerance ensures that that mark is within the allowable variation. When cutting materials such as graphite coated paper, the measurable tolerances are usually tight, and you can expect to be held within a +/- 2mils. Thicker grades and complex geometries may affect the overall tolerance to a +/- 3mils.

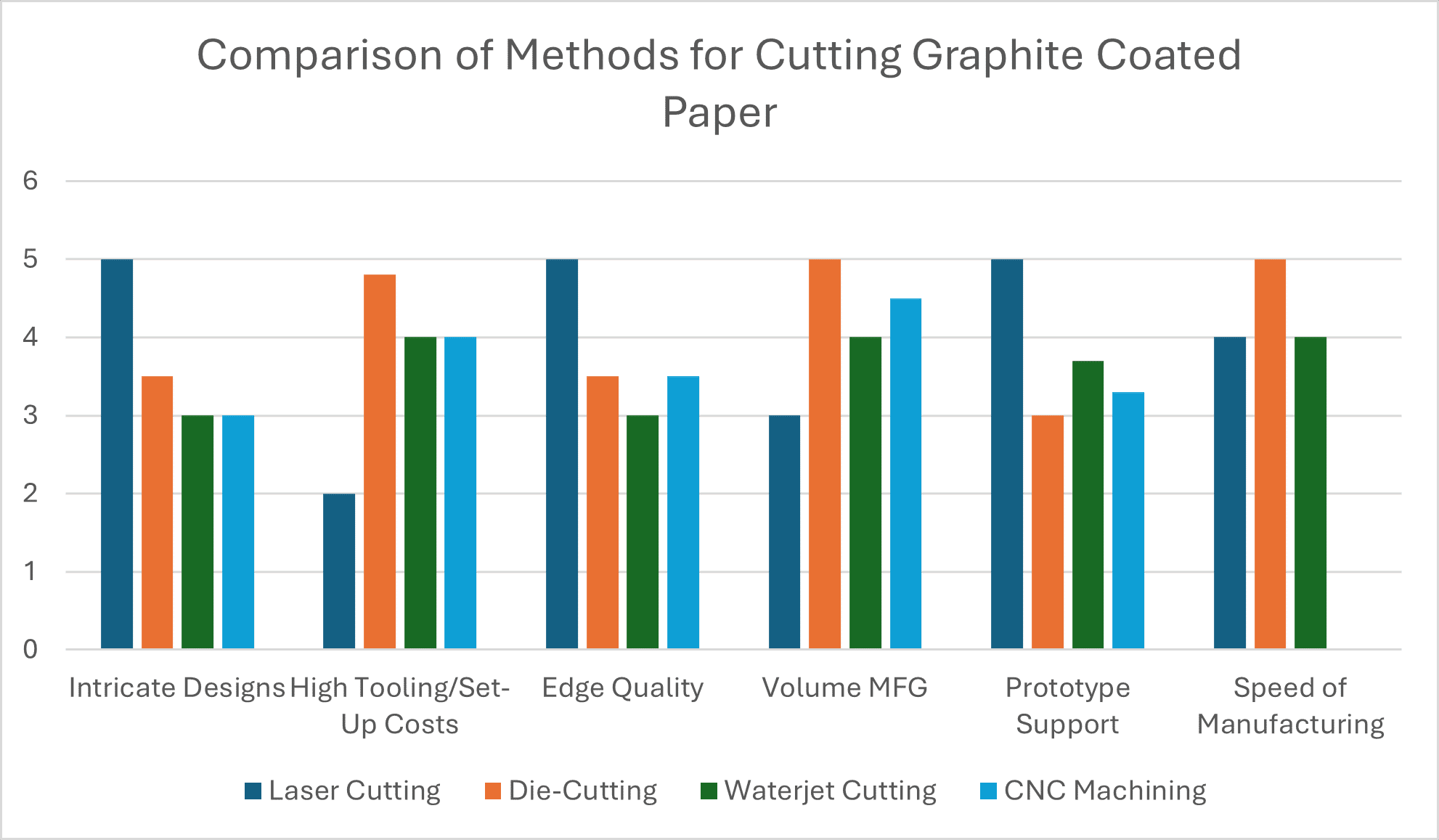

How Does Laser Cutting Compare to Die-cutting, Waterjet, or CNC Machining of Double-Sided Graphite Coated Paper?

Manufacturing in many instances is not a process that is only done by one method, but rather a part can be made by multiple ways. For material such as graphite coated paper however, the nature and chemical properties warrant processes that are better suited for cutting such materials. The following chart is a comparison of this but should not reflect on each manufacturing method’s overall capability.

How Do Material Characteristics Like Reflectivity, Softness, or Thermal Conductivity Affect Edge Quality and Tolerance Control in Double-Sided Graphite Coated Paper?

Every material, whether metallic or non-metallic, has a unique chemical basis that affects how the material reacts to the manufacturing process. These characteristics of reflectivity, softness, thermal conductivity and others must be adjusted to result in optimum edge quality. Adjustments during the manufacturing process is true for every method used to produce precision parts and regarding laser cutting technology, it is important to match the best laser processing to the material. For DSGCP, using a UV laser (ultraviolet) is a great fit although adjustments to parameters will need to be done and monitored.

What Edge Quality Can Be Expected When Laser Cutting Double-Sided Graphite Coated Paper? Are Burrs or Heat-Affected Zones (HAZ) Present?

Cutting double-sided graphite coated paper with a laser generally yields excellent edge quality due to the non-contact, high-energy process vaporizing the carbon material cleanly. Regarding your DSGCP project you should expect the edges to be very sharp and precise, making laser cutting the preferred method for tight tolerances. While true burrs (raised metal edges) are absent since the material doesn’t melt and resolidify like metal, a slight Heat-Affected Zone (HAZ) is typically present. This HAZ manifests as a narrow band of discoloration or charring immediately adjacent to the cut line, caused by the high in-plane thermal conductivity of the graphite spreading heat outward; however, this zone is usually minimal and acceptable for most applications, provided the laser parameters (power and speed) are properly optimized.

What Are the Benefits of Laser Cutting Double-Sided Graphite Coated Paper?

Absolutely there are many benefits to using laser cutting for DSGCP and for many other materials for reliable and precision focused flat parts and components. The following benefits can not only be applied to graphite-based type of substrates but to the wide array of materials A-Laser processes.

Ablation Efficiency (High Material Absorption):

Graphite absorbs laser energy efficiently, enabling fast, clean cuts without excessive heat.

Superior Edge Quality and Precision:

Laser cutting creates sharp, clean edges with a narrow kerf and avoids mechanical damage like tearing or fraying. This ensures tight tolerances needed for precise components such as fuel cell gaskets and battery heat spreaders.

Minimal Risk of Damage (No Mechanical Stress):

The non-contact process means no force is applied to the graphite, preventing crushing, flaking, or delamination and preserving its properties.

Flexibility & Cost Control

Laser cutting uses CAD files, eliminating tooling costs and allowing quick design changes and prototyping. It enables complex shapes and fine features that die-cutting cannot achieve, making it ideal for microelectronic and thermal management parts.

Ablation Efficiency (High Material Absorption):

Graphite absorbs laser energy efficiently, enabling fast, clean cuts without excessive heat.

Flexibility & Cost Control

Laser cutting uses CAD files, eliminating tooling costs and allowing quick design changes and prototyping. It enables complex shapes and fine features that die-cutting cannot achieve, making it ideal for microelectronic and thermal management parts.