Laser Cut Cupronickel Service

Trusted by

1,000’s

of Satisfied Customers

30+

Years in Business

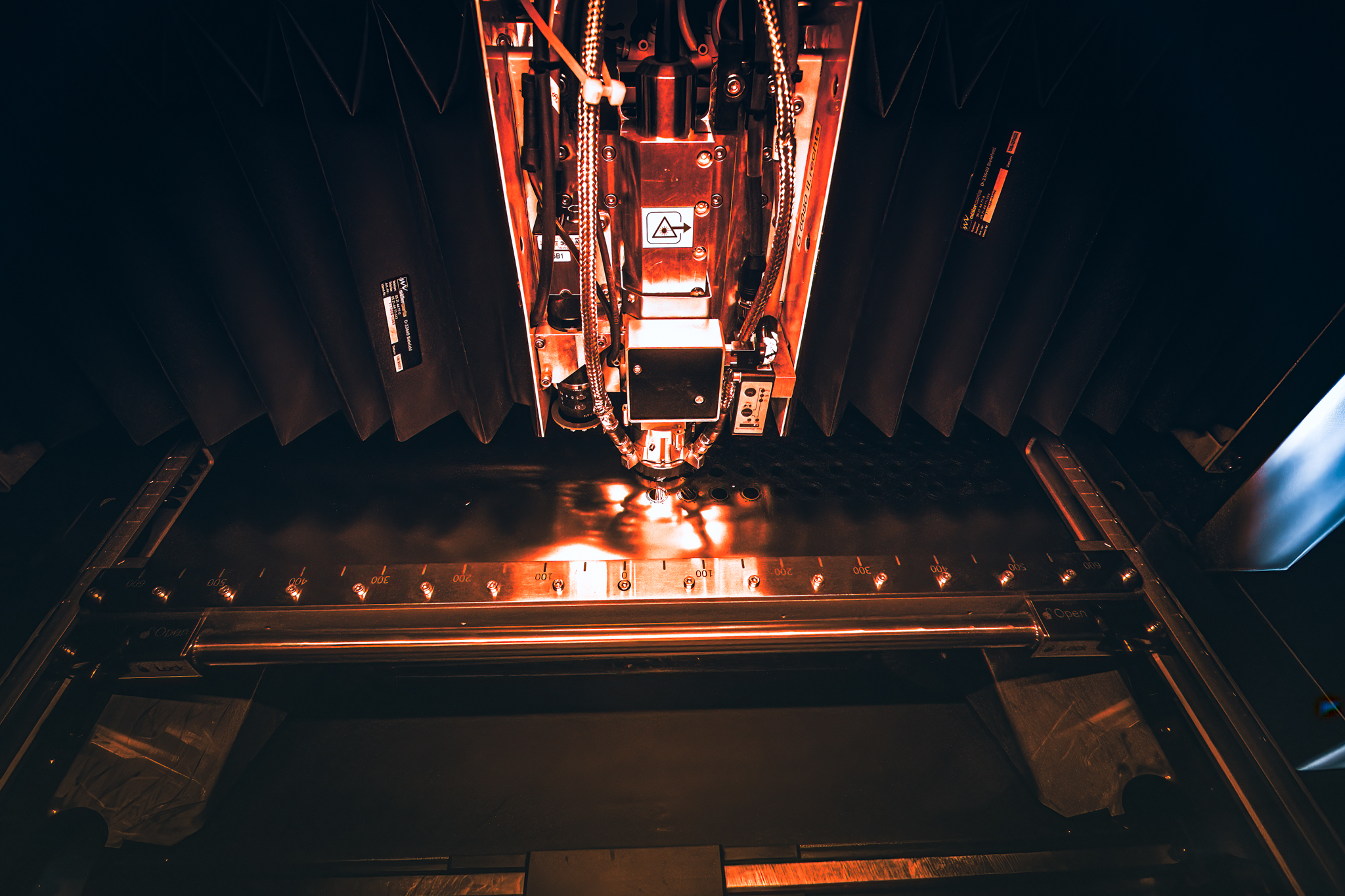

Cupronickel combines the strength of copper with the stability of nickel, creating a versatile alloy trusted for precision components in demanding environments. Cupronickel is typically composed of 70–90% copper and 10–30% nickel. These alloys offer a unique balance of corrosion resistance, ductility, and thermal stability that have supported critical industries since the early 1900s. Its characteristics have become the material of choice for marine, energy, and electronic applications. Today, laser cutting elevates Cupronickel’s potential even further by delivering clean, accurate edges and intricate geometries. This maintains dimensional accuracy within microns, producing clean, oxide-free edges with minimal heat distortion that traditional machining cannot match. From fine electrical connectors to custom heat exchanger plates, laser-cut Cupronickel parts bring consistent performance and longevity to industries where precision truly counts. We are happy to learn more about your project’s needs, but in the meantime, the following Q&A are provided for more insight of laser cut cupronickel.

Laser Cut Cupronickel Accuracy

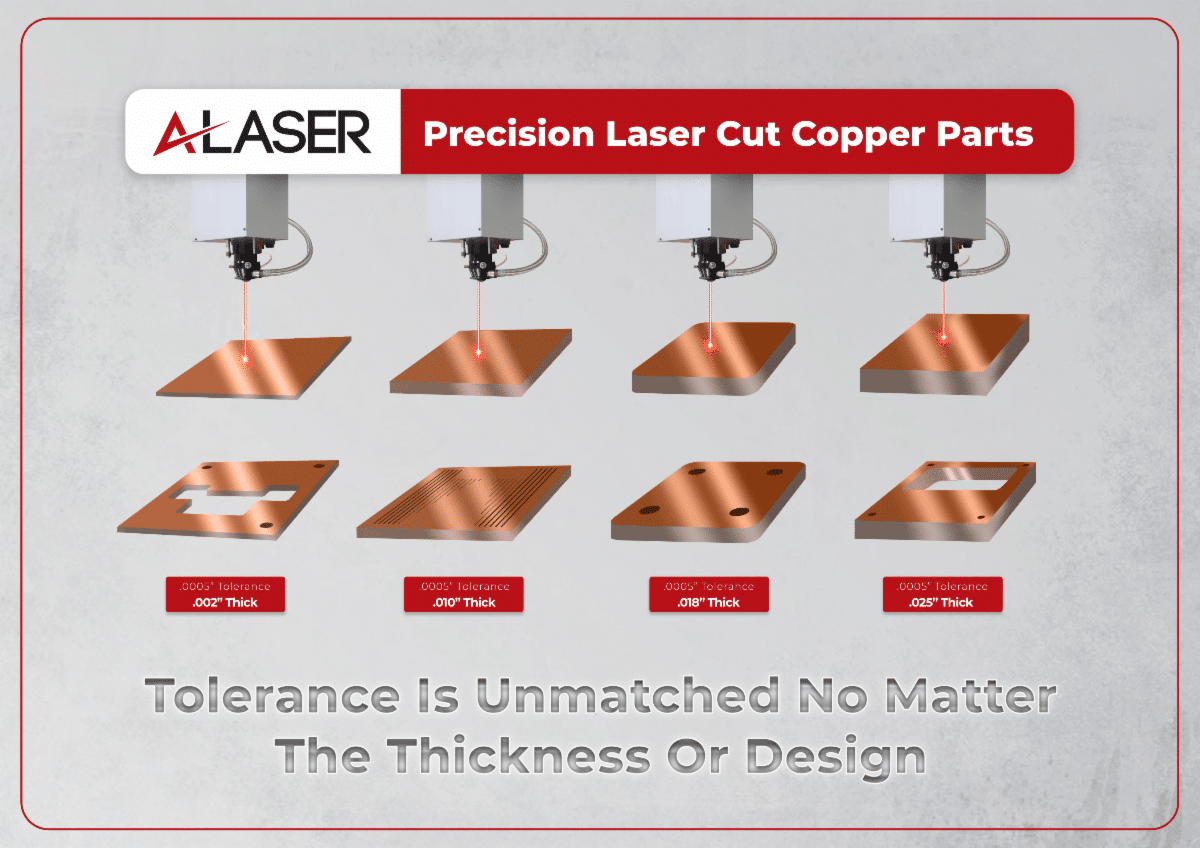

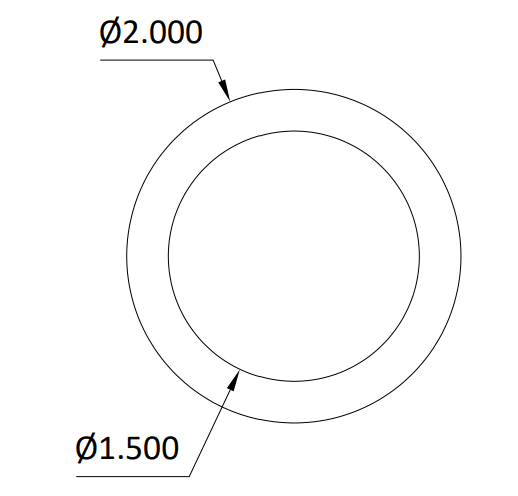

What Are the Tightest Tolerances Your Laser Cutting Process Can Maintain When Cutting Cupronickel?

Laser cutting brings an impressive level of precision to Cupronickel parts, even in very thin or detailed designs. With a UV laser, thin foils up to about 8 mils thick can be cut with remarkable accuracy by holding tolerances as tight as ±0.5mil to ±1 mil. For thicker Cupronickel, typically between 10 and 20 mils, fiber lasers keep that same high level of control, achieving around ±1mil to ±2 mils. The result is smooth, clean edges and consistent part dimensions which are perfect for industries that demand tight fits, reliable performance, and repeatable quality every time.

How Methods Compare

How Does Laser Cutting Compare to Die-cutting, Waterjet, or CNC Machining of Cupronickel?

When it comes to shaping Cupronickel, traditional methods like die-cutting, waterjet, or CNC machining each have their place, but laser cutting offers a level of precision and flexibility that stands apart. Because the process is non-contact, there’s no tool wear or mechanical stress on the material, which helps preserve Cupronickel’s smooth surface and fine details. Waterjet cutting can handle thicker stock but lacks the edge cleanliness and micron-level accuracy lasers deliver. CNC machining offers good control but can introduce burrs and requires more finishing time. In contrast, laser cutting produces crisp, repeatable parts with minimal heat-affected zones, making it the ideal choice for intricate components or high-specification applications.

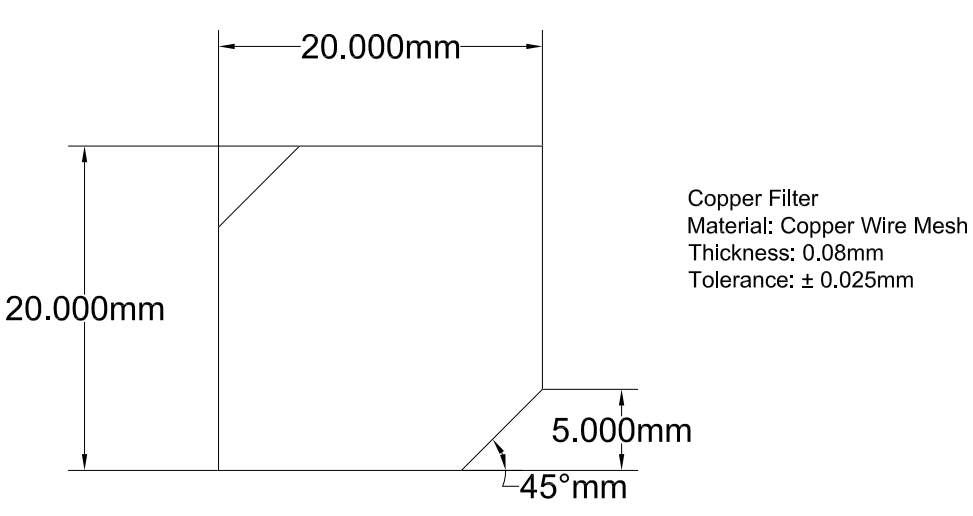

Material Characteristics

How Do Material Characteristics Like Reflectivity, Softness, or Thermal Conductivity Affect Edge Quality and Tolerance Control in Cupronickel?

Laser cutting of metal alloys requires extensive knowledge of how these materials react to thermal stress. Laser cutting is not a mechanical process, as in some other methods, but it can however incur thermal stress into materials during the cutting process. The characteristics of reflectivity, softness and thermal conductivity can all influence edge quality and tolerance control. A-Laser specialists adjust parameters according to material characteristics of each project. Examples of these are shown below:

- Reflectivity: Cutting by ultraviolet (UV) or fiber lasers, the reflectivity of cupronickel or other shiny metal can be challenging. If not, enough power is used, an inconsistent cut will result, and too much power can deform or “oil can” the cut area. Laser parameters that include power, laser frequency, laser passes and others are refined to make the optimum tool settings for quality cut.

- Softness: Metal alloy softness does not affect laser cutting as in mechanical methods like CNC machining, where slag and burrs can be gummy. However, the laser parameters, as mentioned will by tuned to optimize the efficiency of the cut and minimize edge burr formation. Post processing techniques like tumble deburring, sanding, or electrical polishing may be done.

- Thermal Conductivity: Cupronickel alloys have a relatively high coefficient of thermal expansion. To achieve the best tolerance of laser cut cupronickel parts, Additional laser passes, and power settings controls are done. During the process, F.A. (First Article) inspections are conducted and measured to confirm geometry before ongoing production is made.

Edge Quality Results

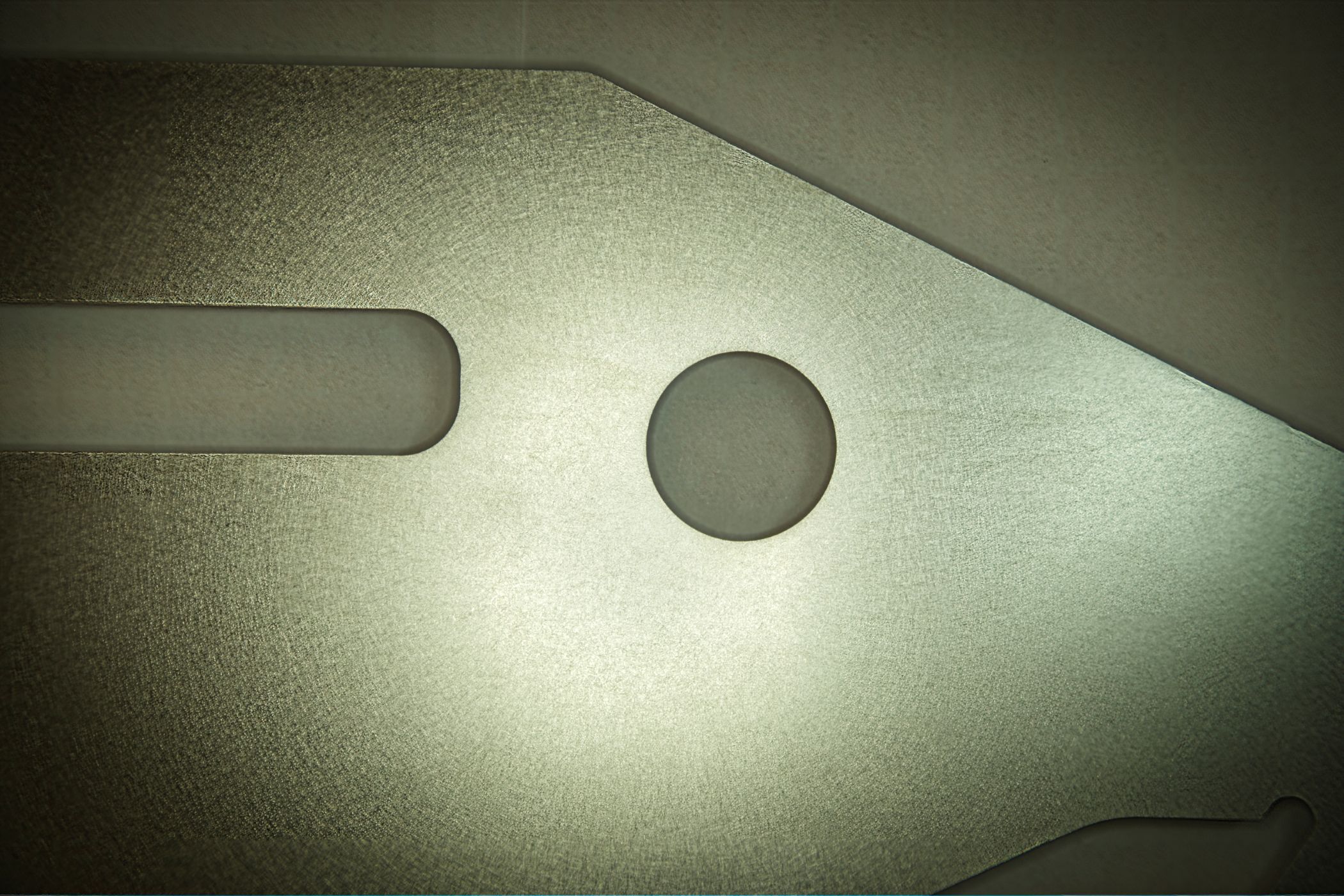

What Edge Quality Can Be Expected When Laser Cutting Cupronickel? Are Burrs or Heat-Affected Zones (HAZ) Present?

Edge quality is one of the recurring reasons projects are moved to laser cutting service providers. To keep the expected high standards in place, laser specialists work through each project’s unique challenges. For laser cut cupronickel you can expect the following:

- The edge will be quite smooth and clean, especially when using an assist gas like nitrogen, which helps prevent oxidation and improves the cut part.

- The surface finish is typically excellent, often meeting the requirements of complex electronic, marine, or decorative components without needing heavy secondary finishing.

- With a fiber laser and appropriate process control (like proper gas pressure, speed, and focus), you can achieve a virtually burr-free edge. This is a major advantage of laser cutting over traditional mechanical methods for this alloy.

- If a burr does form, it is usually just a very light, dross that is only loosely attached and can be easily removed. For high-precision parts, a quick, light sanding or tumbling step can ensure a perfectly clean edge.

- For most applications, this small HAZ will occur but does not significantly degrade the part’s function.

Closing Insights

What Are the Benefits of Laser Cutting Cupronickel?

So, what does all this mean for your project? Essentially, laser cutting cupronickel delivers the best of all worlds. You get the incredible precision needed for complex electronic and marine parts, the speed that keeps costs down, and the clean, near-perfect edge quality that avoids the burrs and rough finish of traditional machining. Because the process is so controlled, it minimizes the heat stress on the metal, preserving cupronickel’s excellent corrosion resistance and ensuring your parts are ready for immediate, high-performance use. If you need intricate, durable, and reliable cupronickel components, switching to laser cutting just makes sense to take advantage of the technology and ensure quality without compromise.