For laser cut precision parts, fiber lasers can increase efficiency in the manufacturing process of metal alloy components. Efficiency is an ongoing challenge for manufacturing and becoming and sustaining an efficient process increases productivity, profitability and customer satisfaction. Laser manufacturing is just one of many methods available to produce precise geometries and many of these are made to support critical industries. Components produced out of metal alloys encompass a wide range of characteristics such as thermal range, strength, machinability, temper, electrical conductivity and other factors, serving countless industries for countless applications.

Fiber lasers, in comparison to other laser systems such as pico-second, femto-second, ultraviolet, and CO2 lasers, offer several advantages in terms of efficiency and application suitability. Pico-second and femto-second lasers, known for their ultra-short pulse durations, are exceptional for precision applications requiring minimal thermal impact. However, they are often more expensive and complex to operate, cutting extremely thin alloys. Ultraviolet lasers provide high absorption in a variety of materials, making them ideal for fine patterns and micro-machining but are limited by their lower power levels. CO2 lasers, emitting at a wavelength of 10.6 micrometers, are highly effective for cutting and engraving non-metallic materials; however, their efficiency drops significantly when used for cutting metals due to their poor absorption in most metallic materials. The following table demonstrates how fibers lasers can be a great benefit for metal precision parts.

| Laser Type | Wavelength | Pulse Duration | Material Suitability | Efficiency in Metal Cutting |

|---|---|---|---|---|

| Pico-second | Varies | 10-12 seconds | High precision, minimal thermal impact. Good for ultra-thin material applications | Moderate |

| Femto-second | Varies | 10-15 seconds | Ultra-high precision, minimal thermal impact. Ultra-thin material applications. | Moderate |

| Ultraviolet | 200-400 nm | Continuous or pulsed | High material absorption, fine patterns. | Low |

| CO2 | 10.6 µm | Continuous or pulsed | More efficient for non-metallic materials | Low |

| Fiber | 1.07 µm | Continuous or pulsed | Metals, high power density | High |

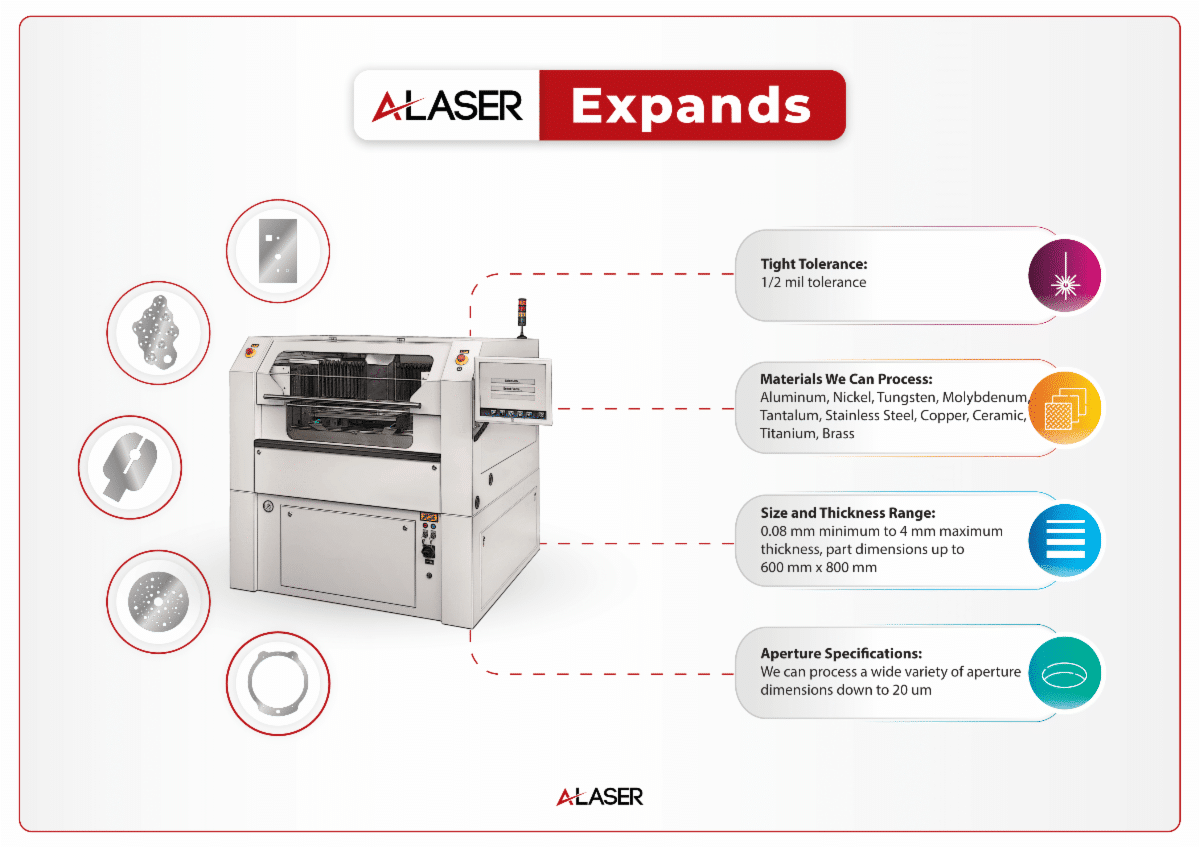

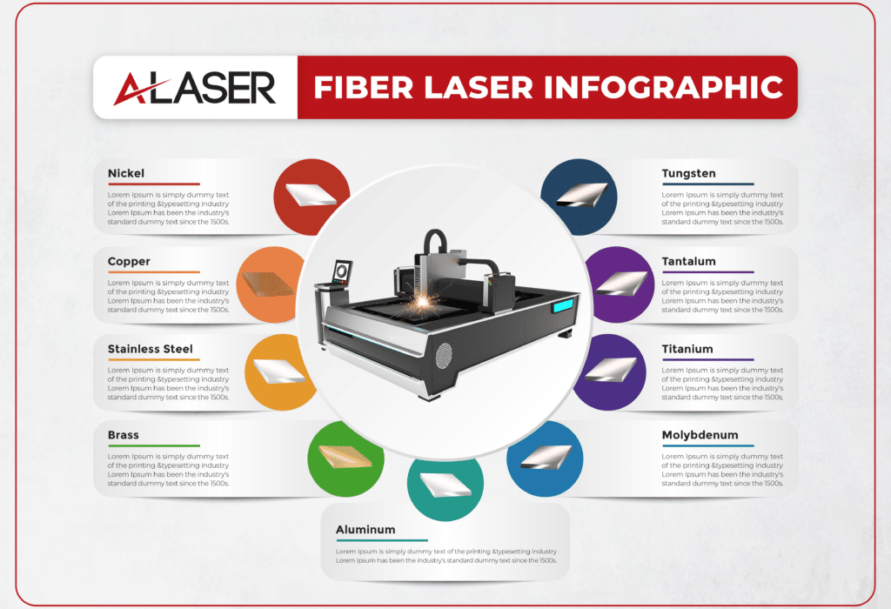

The table indicates the fiber laser advantage, but that does not mean fiber lasers are the overall best laser type for cutting metallics. That option is really determined by the design factors per project. Micro-machining of thin metal foils is better processed by pico-second, femto-second or ultraviolet machines. Fiber laser cutting technology has a broader capability window for thicker gauges of metals from about 0.254mm up 4mm, 10mm plates and higher depending on the wattage of the laser system.

Fiber lasers, on the other hand, utilize a solid-state gain medium and operate at a wavelength of approximately 1.07 micrometers, which is highly absorbed by metals. This results in faster and more precise cuts with less energy consumption. The fiber delivery system allows for tighter focusing of the laser beam, leading to higher power densities and increased cutting speed. Additionally, fiber lasers are more compact, have lower maintenance costs, and boast higher electrical efficiency compared to CO2 lasers. The combination of these factors makes fiber lasers more efficient and cost-effective for metal cutting applications.

Fibers Laser and Other Manufacturing Methods

Fiber lasers can be more efficient than other manufacturing methods but that does depend on the projects size, the design and metal being processed. The general type of precision component from laser cutting is a 2D flat part. Medical stents and similar tube-like parts are made by using laser technology, but those laser systems are designed for tube like components. Fiber lasers and laser technology excels in 2D parts with the range of metallic materials that can be cut and flexibility to support R&D and prototyping, that can transition to high volume manufacturing. They do not require in most cases any additional tooling, nor require costly cast dies or special set-up. This itself is advantageous and well known to manufacturers. Though high-speed CNC machining or stamping have been the go-to for volume manufacturing, they cannot support nor be as efficient as fiber lasers when handing mid-level volumes. Strategic planning is needed for any manufacturing job and by doing so with a fiber laser, multiple designs can be cut out of the same sheet of metal. This process can be done repeatedly and with an accuracy of +/- 0.0254mm. Material selection requires only a change to the laser parameters (speed, wattage, frequency, dwell time, laser passes and others), with no additional tooling cost. Another advantage of fiber lasers is the characteristics of the cut profile. While CNC machining is excellent at 3,4 and 5 axis parts, they need to slow down at thinner gauges. Care of programming and parameters are necessary to prevent damage to thinner metal sheets or plates. Stamping has limitations on thickness and can result in a rounded edge of the stamped part. This is undesirable for many applications. Fiber lasers can produce the needed precision with straight walls and exact duplication.

In conclusion, fiber lasers significantly enhance the efficiency of manufacturing precision metal components by offering unmatched accuracy, flexibility, and repeatability. Their ability to precisely cut multiple designs from the same metal sheet without the need for extensive tooling adjustments streamlines the production process and reduces turnaround time. This high level of efficiency, coupled with superior edge quality and minimal material waste, positions fiber lasers as an indispensable tool in modern manufacturing, enabling the production of complex and high-quality parts with remarkable consistency.