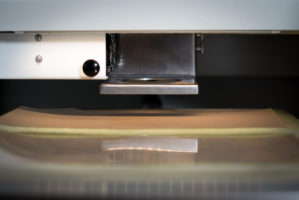

Can Lasers Cut Plastic?

“Can lasers cut plastic?” The answer to that question is both yes and no. It all depends on the type of plastic and polymer, and the laser systems available for your project. Below is a brief overview of laser systems used in general manufacturing, and in precision parts manufacturing.

Lasers are used for these applications and more:

- Laser cutting

- Laser marking

- Laser welding

- Laser heat treating

- Laser surface ablation

- Laser soldering

Each service provider either has their own proprietary laser technology, or uses systems developed by laser manufacturers. In my experience, there are no ‘best’ systems, but there are systems dedicated to cut specific materials and which have specific uses. CO2 lasers or Carbon Dioxide lasers cut a variety of materials well, including clear plastics like acrylic and polycarbonate.

NdYAG laser systems can be adjusted for power output and frequency and can cut materials like polyimides, flexible epoxies, metalized materials like grafoil as well as stainless steel. Many applications cut on NdYag lasers can be cut with adhesives, allowing for a broader range of manufacturing opportunities. The versatility of these lasers which makes them very popular in the service industry.

Excimer laser systems use higher power UV technology and have been used in surgical applications as well as in lab research. They are moving into use in production, but are not yet as widely used in this role.

When it comes to plastics, NdYAG UV lasers will cut polyimide (Kapton) and poly ether ketone (PEEK) very well. Polypropylene, polycarbonate are better suited to CO2 laser systems.

Because laser technology is focused light energy, there is often carbon residue and/or discoloration on the laser-cut edge. This may or may not affect the use and application of the project for the end user, so it’s important for the service provider to communicate with the end user in order to facilitate review and feedback and ensure a satisfactory final product.

One main advantage of laser technology is that it allows for quick-turn processing and also allows for the design and research process to happen more rapidly than other technologies such as die-cutting. Every situation provides a new challenge and service providers should advise which is the best option.

Lasers can cut plastics. There are many advantages to their use with these materials. The accuracy, the small beam diameter, and the end use sometimes make lasers the only option available. As our technology moves forward, more and more manufacturing requirements will call for tighter tolerances and precision accuracy. Laser technology will be there to support this growing demand. A little research is all it takes to discovery the many benefits of laser technology, and which might be right for you.

Good luck on your next project and I hope to hear from you!

About the Author

Joe has been part of the A-Laser team for over 10 years and has extensive experience with laser cutting technology, sales, and customer service. Joe was born and raised in San Jose, CA and has resided with his family in Gilroy, CA since 1997. The unique projects he gets to learn about and the industries they support, keep everyday new! His hobbies include photography, he is a member of the Morgan Hill Photography Club, hiking, model building and collecting vintage camping lanterns and stoves. His favorite places include Mount Lassen Volcanic National Park, Portland OR, and Boston MA.