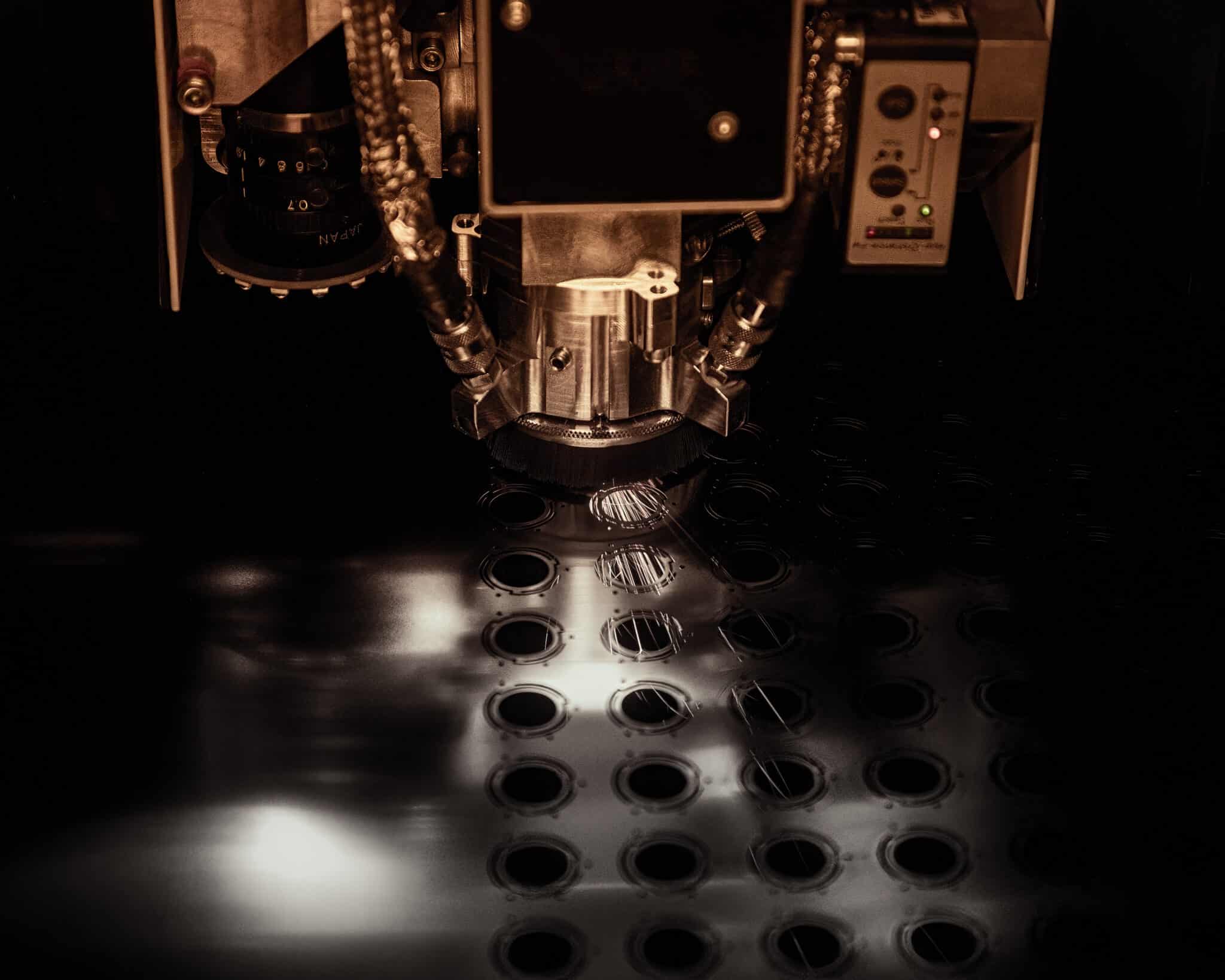

Laser Cut Blue Spring Steel Service

Blue Spring Steel is known for its strength, elasticity, and ability to hold a fine edge. It is these qualities that make it a favorite in precision components like clips, fasteners, and springs. When paired with laser cutting, this material’s performance potential is fully realized. Modern laser systems offer a clean, consistent way to produce intricate parts with minimal distortion or tooling limitations. Below, we answer common questions about what to expect when laser cutting Blue Spring Steel, including achievable tolerances, edge quality, and how this process compares to other manufacturing methods.

Tolerance Expectations

What Are the Tightest Tolerances Your Laser Cutting Process Can Maintain When Cutting Blue Spring Steel?

When precision matters, laser cutting delivers. Using high-stability fiber laser or UV laser systems, Blue Spring Steel can be cut to tolerances as tight as ±0.001–0.002 inches (±25–50 microns), depending on material thickness and design complexity. This precision ensures your components—such as clips, shims, and precision washers—fit perfectly without additional machining or finishing.

Comparing Manufacturing Methods

How Does Laser Cutting Compare to Die-cutting, Waterjet, or CNC Machining of Blue Spring Steel?

| Process | Precision | Edge Finish | Tool Wear | Complexity Handling | Material Waste |

|---|---|---|---|---|---|

| Laser Cutting | ±0.001–0.002 in | Clean, burr-free | None | Excellent for intricate profiles | Minimal |

| Die-cutting | ±0.005–0.010 in | Good, may require deburring | High | Limited by tooling | Moderate |

| Waterjet | ±0.003–0.005 in | Smooth, no heat effects | None | Good, slower for fine detail | High |

| CNC Machining | ±0.0005–0.002 in | Excellent | High | Slower for thin materials | Moderate |

Laser cutting combines speed, flexibility, and accuracy, making it the go-to choice for Blue Spring Steel when every detail counts. With no tooling to maintain or replace, production runs are faster, cleaner, and more adaptable than with traditional cutting methods.

Considering Characteristics

How Do Material Characteristics Like Reflectivity, Softness, or Thermal Conductivity Affect Edge Quality and Tolerance Control in Blue Spring Steel?

Blue Spring Steel’s high reflectivity, hardness, and thermal properties require precise control—and that’s where modern laser systems excel.

- Reflectivity is balanced through optimized wavelength and beam focus, ensuring steady energy absorption.

- Hardness enables crisp, stable cuts that preserve form and performance.

- Thermal Conductivity allows localized heat control, minimizing distortion and maintaining dimensionally stable edges.

The outcome: consistent, sharp, and repeatable cuts—even on thin, hardened stock.

HAZ and Edge Quality

What Edge Quality Can Be Expected When Laser Cutting Blue Spring Steel? Are Burrs or Heat-Affected Zones (HAZ) Present?

When properly tuned, the laser cutting process leaves a narrow Heat-Affected Zone (HAZ), typically under 30 microns deep. Edges appear bright, uniform, and free of burrs or oxidation, maintaining the spring’s surface integrity and mechanical properties. The result is a part that not only looks clean but performs exactly as engineered.

Keep These Points in Mind

What Are the Benefits of Laser Cutting Blue Spring Steel?

- No tooling costs or wear, ideal for quick design changes or low-volume runs.

- Exceptional precision and repeatability, even on complex geometries.

- Clean, burr-free edges that maintain the material’s spring performance.

- Reduced waste and faster lead times, helping accelerate your production cycle.

- Reliable quality across production volume, with digital precision at every step.

Laser manufacturing can be solid method for many industry applications and devices where maintaining precision is a critical factor. Supporting R&D with prototypes and product development has assisted countless progression of high-tech. Although laser cutting machines may be the only option for certain projects, others will have multiple methods to consider. We are happy to review and discuss your project in detail and determine if our services are a great fit.