Laser Cut Nitto Tape Service

Nitto tape is a trusted adhesive solution widely recognized for its exceptional performance in industrial applications, particularly where precision and reliability are paramount. Originating from Nitto Denko Corporation, a Japanese company established in 1918, Nitto tape has evolved over the decades to become a staple in both traditional and advanced manufacturing sectors. Known for its clean adhesion, easy removability, and resistance to heat and chemicals, Nitto tape finds a special niche in the world of laser-cut flat parts and components. In these applications, its protective qualities help prevent surface damage, reduce residue, and ensure crisp edges during the laser cutting process. Whether used for masking, protection, or holding delicate materials in place, Nitto tape enhances the quality and efficiency of laser-cut products, making it indispensable for manufacturers working with precision 2D components. For further insight into Nitto tape and laser cutting technology, the following Q&A are provided.

Precision of Laser Cut Nitto Tape

What Are the Tightest Tolerances Your Laser Cutting Process Can Maintain When Cutting Nitto Tape?

When cutting Nitto tape with precision laser systems, our process achieves remarkably tight tolerances that ensure consistent, production-ready results. Using a UV laser, we can maintain tolerances within +/- 0.5 mil to +/- 1mil on thin Nitto films for most cut designs. This makes it ideal for adhesive-backed layers or fine-featured components where clean edges and minimal heat are critical. For the most demanding applications, such as micro-patterning or ultra-fine die replacement, our femtosecond laser technology pushes precision even further, reaching tolerances as tight as +/- 0.25 mil. These capabilities allow us to produce highly accurate parts with crisp, debris-free edges and no adhesive distortion, even on multilayer or heat-sensitive Nitto tape constructions.

Methods of Manufacturing

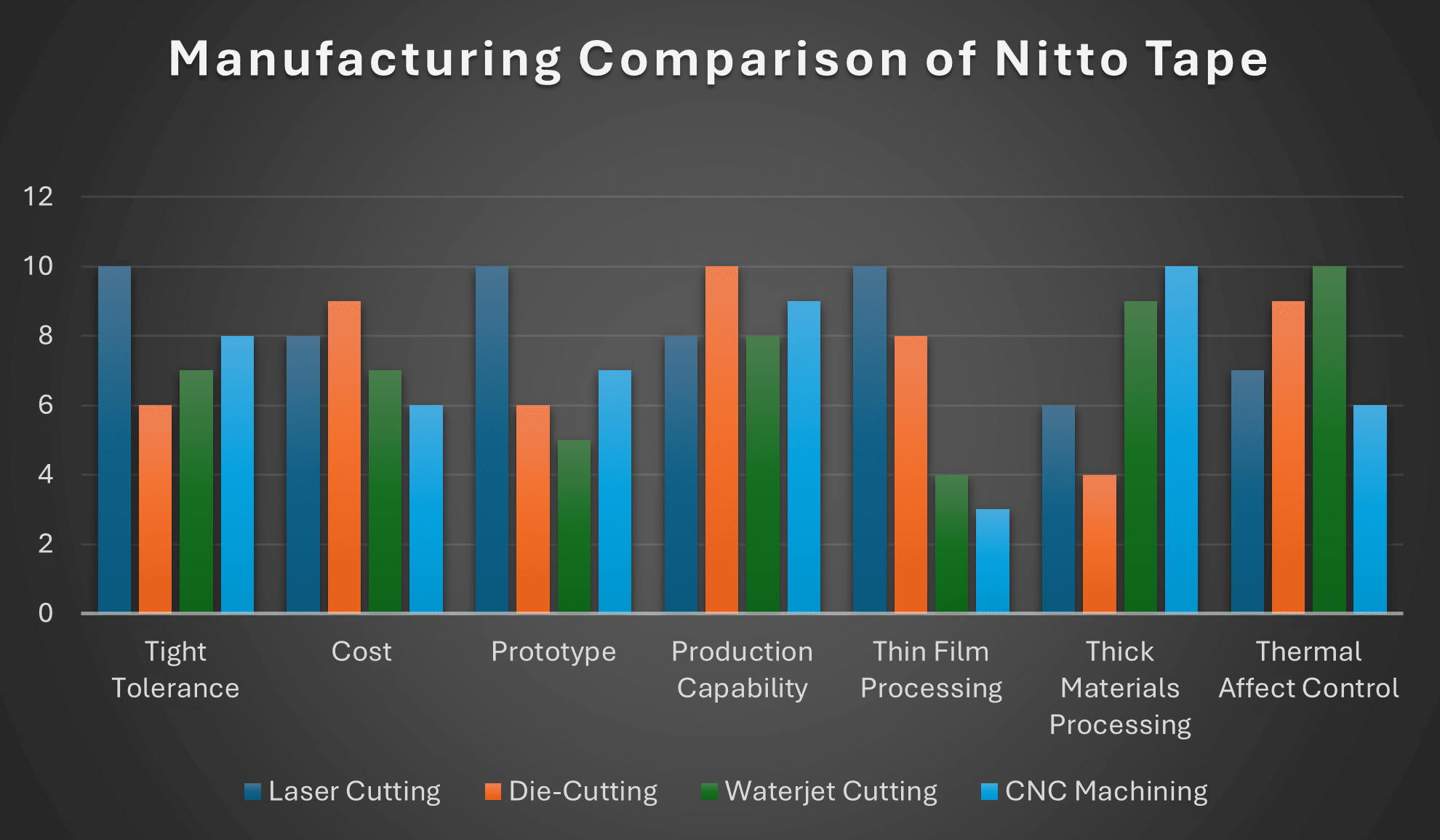

How Does Laser Cutting Compare to Die-cutting, Waterjet, or CNC Machining of Nitto Tape?

This comparison is a general overview of the methods compared in processing Nitto tape and other similar film and sheet materials. It is not a conclusion to the best overall methods of manufacturing flat 2D components, as each project will have unique factors that may be better suited to one method of manufacturing.

Characteristically Nitto Tape

How Do Material Characteristics Like Reflectivity, Softness, or Thermal Conductivity Affect Edge Quality and Tolerance Control in Nitto Tape?

In laser cutting Nitto tape, material characteristics such as reflectivity, softness, and thermal conductivity play a key role in achieving clean edges and tight tolerances. The low reflectivity and soft, adhesive-backed nature of Nitto tape allow the laser to absorb energy efficiently, producing smooth, burr-free cuts without scattering or beam loss. Its relatively low thermal conductivity helps localize heat, minimizing distortion and preventing adhesive bleed or edge charring. These factors together enable precise control over beam interaction, resulting in crisp, consistent features even at micro-scale dimensions.

Edge Quality

What Edge Quality Can Be Expected When Laser Cutting Nitto Tape? Are Burrs or Heat-Affected Zones (HAZ) Present?

Nitto tape cuts very well using laser cutting techniques and results in very accurate and reliable components for numerous industry applications. Examples of these are for use such as wearable medical devices with adhesive Nitto tapes, for the automotive industry for use as fasteners and other bonding applications. Nitto tape is used in electronic displays for bonding components and for securing batteries and other electronics. These industries require premium edge quality and that is supported by manufacturing processes such as laser technology applies. For laser cut Nitto tape you can expect the following:

- Exceptionally Clean Edges: Laser cutting produces sharp, well-defined edges with no fraying or tearing of the film or adhesive layer.

- No Burr Formation: Since the process is non-contact, there’s no mechanical drag—meaning burrs or raised edges are virtually eliminated.

- Minimal to No Heat-Affected Zone (HAZ): Using UV or femtosecond lasers keeps the heat input extremely localized, preventing melting, discoloration, or adhesive distortion.

- Consistent Edge Integrity: Even on multilayer or pressure-sensitive versions of Nitto tape, the edges remain smooth, clean, and repeatable across high-volume runs.

Keep In Mind These Factors

What Are the Benefits of Laser Cutting Nitto Tape?

As demonstrated earlier, laser cutting machines are not the only solution in cutting Nitto tapes, however once the decision has been made and perhaps the only solution for a particular project, these precision components will benefit your project by holding tight tolerances that are supported by ISO 9001-2015 guidelines for inspection and traceability. The ability to support development projects with prototyping and the ability to ramp up production without incurring additional costs, makes laser cutting very versatile. Flexibility also is a big plus in supporting industries with multi-material capabilities. From cutting Nitto tapes to rubber gasketing sheets to metal alloys and other polymers, laser technology can support many critical devices. We are happy to learn more about your project needs and look forward to hearing from you.