Laser Cut Topas E140 Service

Trusted by

1,000’s

of Satisfied Customers

30+

Years in Business

What is thermoplastic polyolefin elastomer (TPO), and what is it used for? To learn more about this material, let’s first become familiar with it as another name, Topas E140. Which is produced by Topas Advanced Polymers. This can also be called a cyclic olefin copolymer (COC) elastomer. Understandably it can be confusing for anyone seeking to learn how Topas E140 can be made into precision components so we at A-Laser, having a great amount of experience in laser cutting plastic materials, have provided this information as a general guide in laser manufacturing. In general, plastics are cut on ultraviolet or CO2 laser systems. We have found that by utilizing UV lasers, we can produce many of the complex geometries necessary for applications in use today. Many of the flat parts we manufacture are indeed applied in industries from electronics, medical devices, aerospace, automotive, telecommunications, alternative energy, acoustics, and so many other intriguing opportunities. For additional information about laser cutting Topas E140, the following Q&A are provided.

More Than One Method

How Does Laser Cutting Compare to Die-cutting, Waterjet, or CNC Machining of Topas E140?

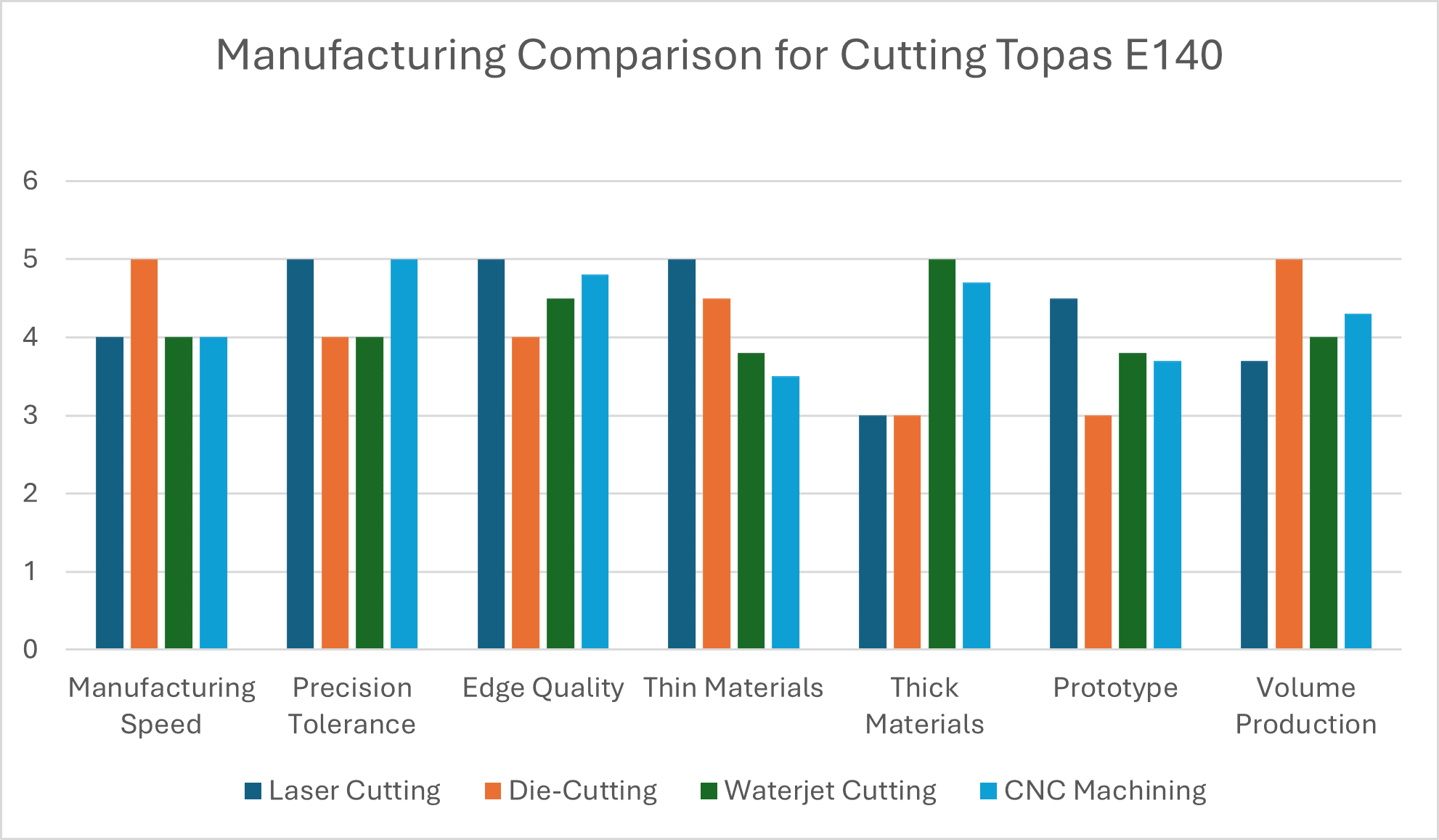

Although each of the manufacturing methods mentioned above are very different in their processing, they can produce similar results, given the details are within manufacturing limits. The following chart is a glimpse of capabilities for each in producing flat 2D components from Topas plastic materials.

As you can see from the chart, there are positive and challenges for each method of manufacturing and applying the best choice should be determined by consultation with your preferred manufacturer.

The Precision of Laser Technology

What Are the Tightest Tolerances Your Laser Cutting Process Can Maintain When Cutting Topas E140?

Achieving tight tolerances is synonymous with laser cutting so when projects come forward with materials such as Topas E140 and similar, you can expect tolerance to be held within +/- 1mil to +/- 2mils for most projects. Variables such as the complexity of the geometry and the thickness of the material can affect tolerance, but you can be assured that once the parameters are set, the components will exhibit high quality from a reliable and repeatable process.

Balancing Materials

How Do Material Characteristics Like Reflectivity, Softness, or Thermal Conductivity Affect Edge Quality and Tolerance Control in Topas E140?

The characteristics of Topas E140 have a direct impact on the effectiveness of various manufacturing methods. The material’s low thermal conductivity means it doesn’t dissipate heat well, which can be a challenge for processes for laser cutting. The heat tends to remain at the cutting point, increasing the size of the heat-affected zone (HAZ) and potentially leading to a melted, discolored, or uneven edge. Its softness and flexibility also require careful handling, as it is prone to deformation. Physical cutting methods like die-cutting and CNC machining, which apply force, can cause the material to smear or deform, making it difficult to maintain tight tolerance control. Conversely, the transparency and low reflectivity of Topas E140 make it a good candidate for laser processing because it absorbs the laser energy efficiently, leading to a cleaner, more controlled cut when parameters like speed and power are optimized. Therefore, for superior edge quality and tolerance, “cold” non-contact methods like laser and waterjet cutting are often preferred over mechanical methods.

Edge Quality Expectations

What Edge Quality Can Be Expected When Laser Cutting Topas E140? Are Burrs or Heat-Affected Zones (HAZ) Present?

For laser cutting Topas E140, the edge quality can be excellent, but it requires careful control of the process parameters due to the material’s thermoplastic properties.

Expected Edge Quality

- Clean and Smooth Edges: When the laser power and speed are optimized, laser cutting can produce very clean, smooth edges. Topas E140’s clarity and low reflectivity help it absorb the laser’s energy efficiently, contributing to a precise cut.

Burrs and Heat-Affected Zones (HAZ)

Burrs: The formation of burrs (excess, solidified material on the cut edge) can occur if the cutting parameters are not optimized. By adjusting the laser power, cut speed, dwell time and frequency, just to name a few, slightly melted edge appearance will be minimized. Unlike abrasive methods like waterjet cutting, the laser melts the material to cut it. This melting is what gives it a finished, smooth look. Burrs are generally less of a problem with flexible polymers like Topas E140 compared to metals

- Heat-Affected Zone (HAZ): A heat-affected zone is an area near the cut line where the material’s properties have been altered by the laser’s heat. Due to the low thermal conductivity of Topas E140, heat is not easily dissipated from the cutting area. This can lead to a more pronounced HAZ, which may manifest as slight discoloration or a change in the material’s rigidity near the cut edge. To minimize the HAZ, it’s crucial to use the right combination of high speed and appropriate laser power as mentioned.

Key Takeaways

What Are the Benefits of Laser Cutting Topas E140?

Creation of precision parts with laser cutting machines produces countless fascinating components for countless applications supporting all levels industry needs. Using laser cutting systems you will gain opportunities such as rapid prototyping, tight tolerance control, material flexibility such as plastics, metal, rubber, and others. Laser cutting for 95% of projects does not require special set-up nor fixtures. This reduces the cost and increases the ability to support a wide degree of projects. Laser is often considered a highly reliable solution for small quantities and for assisting in getting rapid prototyping done,