Laser Cut Platinum-Iridium Service

Trusted by

1,000’s

of Satisfied Customers

30+

Years in Business

Platinum-iridium alloy is a fascinating material that has played a crucial role in various technological advancements. Typically comprised of 90% platinum and 10% iridium this alloy is renowned for its high melting point, corrosion resistance, and biocompatibility. These properties make it ideal for use in medical devices, electrical contacts, and scientific instruments, where reliability and longevity are paramount. How platinum-iridium is transformed into precision components is also fascinating with the use of laser cutting technology. Together with experts in the field of laser manufacturing, alloys such as platinum-iridium are being transformed into more devices that improve the quality of medical diagnostics and treatments, to advancing electronics and uses in aerospace components. Further insight into processing this material using laser technology is given with a series of questions and answers.

More Than One Method

How Does Laser Cutting Compare to Die-cutting, Waterjet, or CNC Machining of Platinum-Iridium?

For flat 2D precision components made from platinum-iridium, the choice of manufacturing method—laser cutting, die-cutting, waterjet, or CNC machining—is a trade-off between precision, speed, cost, and material properties. The following text is general to the prospective methods in handling platinum-iridium.

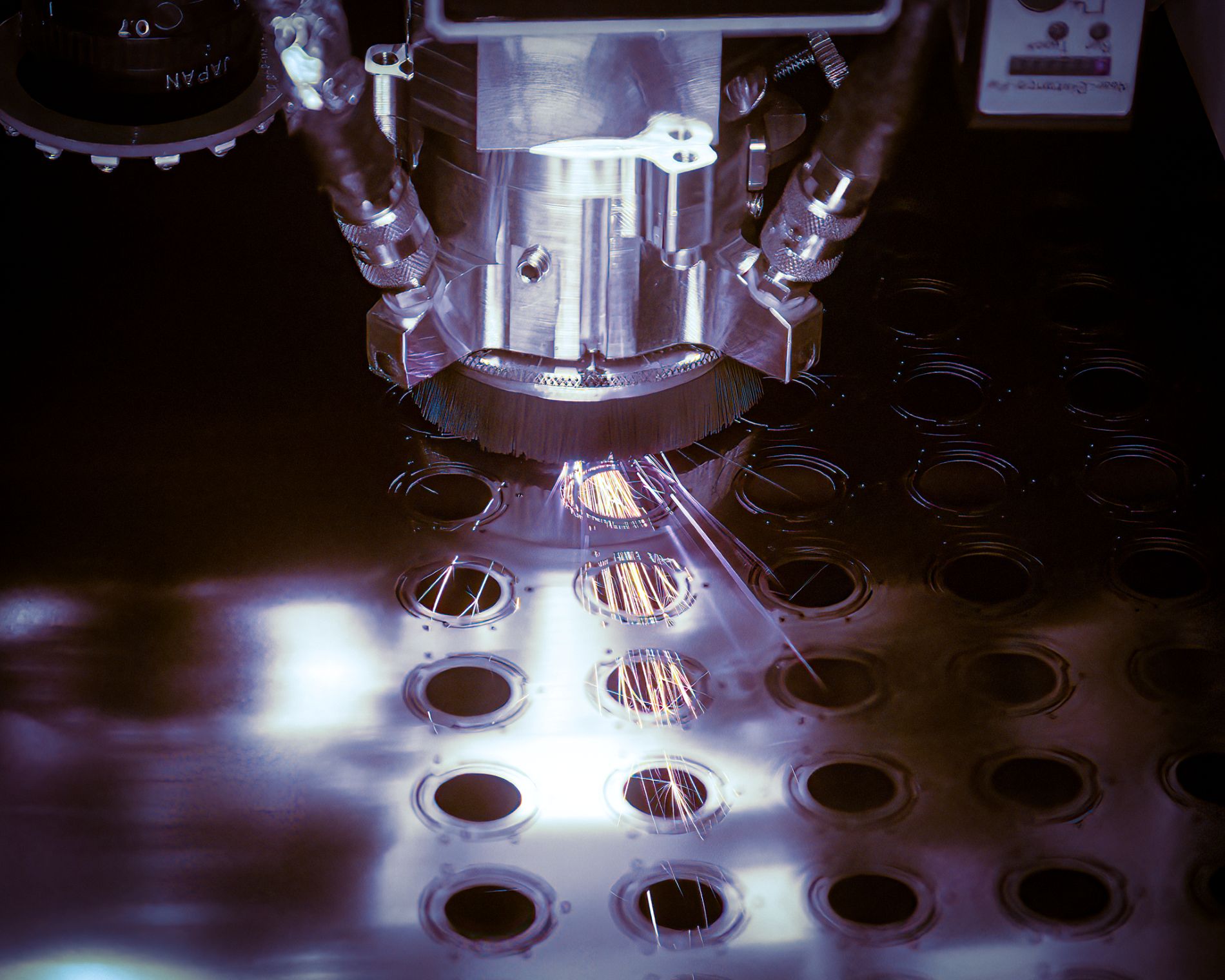

Laser Cutting: It stands out for its speed and precision in creating intricate, complex designs, particularly on thinner sheets of platinum-iridium. It works by focusing a high-powered laser to vaporize the material, resulting in a very narrow cut (kerf) and clean edges. The main challenge is the thermal nature of the cut, which can create a small heat-affected zone (HAZ), potentially altering the material’s properties near the cut edge, though this is often negligible with advanced fiber lasers.

Waterjet Cutting: This method uses a high-pressure stream of water mixed with an abrasive material to erode and cut through the alloy. Its primary advantage is that it’s a “cold” cutting process, meaning it generates no heat and thus eliminates the risk of a heat-affected zone (HAZ). This makes it ideal for cutting platinum-iridium, which is a sensitive and valuable material. Waterjet can handle thicker materials than laser cutting and offers good precision, but it is generally slower and has a wider kerf, making it less suitable for micro-components with extremely fine features.

Die-Cutting: A mechanical process that uses a custom-made steel die to punch or stamp out a shape. It’s an excellent choice for very high-volume production of simple, repetitive shapes due to its exceptional speed and low cost per part once the die is made. However, the initial cost of the die can be prohibitive for small runs or prototyping, and the hardness of platinum-iridium can cause significant wear and tear on the tooling. This method is also less suitable for complex geometries.

CNC Machining: A versatile subtractive manufacturing process that uses a variety of cutting tools to remove material from a solid block or sheet. While CNC is a superior method for creating three-dimensional parts, it can be used for flat 2D components, offering exceptional accuracy and control over part geometry. However, platinum’s “gumminess” and hardness, even when alloyed with iridium, can cause excessive tool wear, making the process slower and more expensive than laser or waterjet cutting.

The Precision of Laser Technology

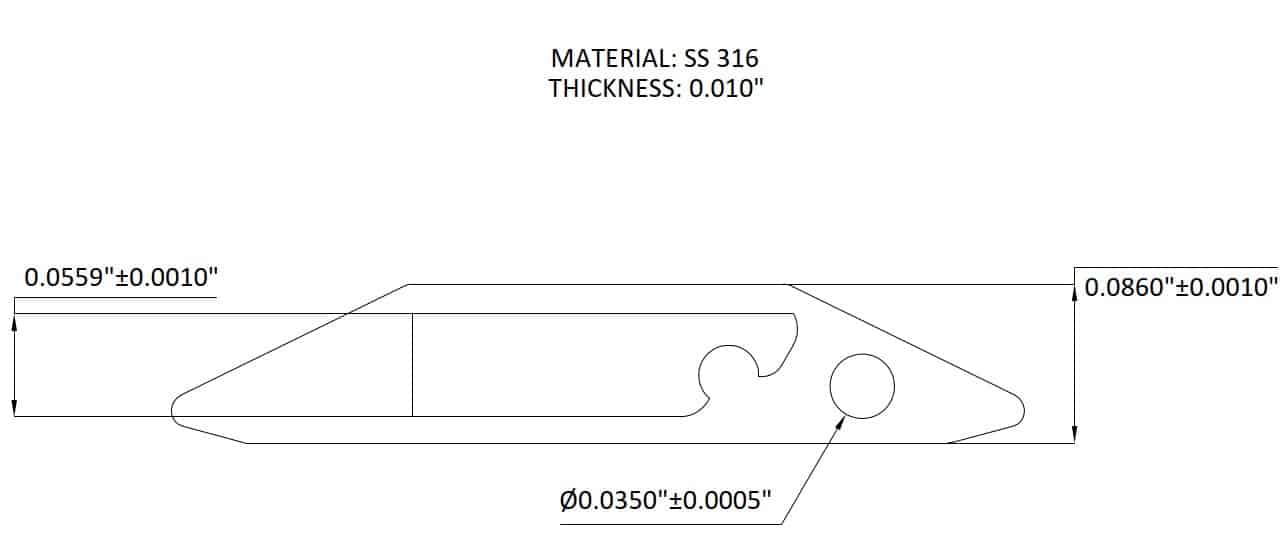

What Are the Tightest Tolerances Your Laser Cutting Process Can Maintain When Cutting Platinum-Iridium?

Producing components for pacemakers or cochlear implants requires the utmost in materials compatibility to its use and environment and the ability to manufacture precisely as required for both the safety of the patient and function of the device. This is the benefit of cutting platinum-iridium with laser cutting machines. Our system can cut ultra-thin foils or sheets of this alloy with tolerances of +/- .5 mil to +/- 1mil for many projects. Measurements are verified using OGP’s (Optical Gaging Products), that confirm overall geometry and individual feature size and shape. Quality is controlled under guidelines of our QMS or Quality Management System, through ISO 9001-2015 guidelines.

Effects of Material Characteristics

How Do Material Characteristics Like Reflectivity, Softness, or Thermal Conductivity Affect Edge Quality and Tolerance Control in Platinum-Iridium?

Material characteristics can affect the outcome of the manufactured part. For a metal alloy such as platinum-iridium, precision parts will be used in many critical applications where defects can be detrimental to the function of the device. To ensure the highest quality possible using laser cutting technology, they must be understood and adjusted too.

Reflectivity: Platinum-iridium’s high reflectivity, especially to the infrared wavelengths, can present challenges. The laser beam can reflect off the surface instead of being absorbed, reducing cutting efficiency and potentially damaging the laser’s optical components. To overcome this, fabricators use fiber lasers, which have a shorter wavelength that is more easily absorbed by metals. Pulsed lasers, such as UV or ultraviolet cutting machines are also used to deliver short bursts of high energy, which helps initiate the melting process and improve absorption.

Hardness: Unlike softer materials that can deform or smear, the high hardness of platinum-iridium is a key advantage for laser cutting. It ensures that the material maintains its shape during the thermal process, allowing for the creation of sharp, clean edges and tight tolerances. This characteristic makes laser cutting an ideal method for producing intricate and complex micro-components without the risk of material distortion.

Thermal Conductivity: Platinum-iridium has a relatively low thermal conductivity compared to pure platinum, which helps to concentrate the laser’s heat in a very localized area. This focused heat allows for a cleaner, more efficient cut and minimizes the heat-affected zone (HAZ), a region of the material where properties may be altered by the heat. This is crucial for maintaining the material’s integrity and ensuring the component’s functionality, especially in sensitive applications like medical devices.

Laser cutting projects are customized and even using platinum-iridium for one project, the parameters, settings and procedures may be very different for another project of the same material. That is what makes laser cutting so interesting and rewarding.

Edge Quality Expectations

What Edge Quality Can Be Expected When Laser Cutting Platinum-Iridium? Are Burrs or Heat-Affected Zones (HAZ) Present?

The goal for our laser cut parts is high-edge quality and when laser cutting platinum-iridium, achieving quality and precision requires being aware of how the laser will react. With adjustments to power, laser cycles or passes, speed of the cut and others, the results can be amazing. Hardness of platinum-iridium results in smooth edges with minimal roughness, which is crucial for components used in sensitive applications like medical implants or aerospace parts. Because laser cutting uses a focused, high-energy beam to vaporize material rather than a mechanical tool to shear it, the process leaves behind minimal to burr-free edge. Concerns of HAZ are overcome by making adjustments to the parameters as mentioned. While no cutting process is perfect, laser cutting provides superior results for this valuable and challenging alloy.

Key Takeaways

What Are the Benefits of Laser Cutting Platinum-Iridium?

Many projects come about for laser processing because other methods cannot produce the fine details required. Platinum-iridium being a challenging alloy to work with, especially in the raw form of thin foils and sheets, are handled and manipulated into profiles with small features using laser cutting techniques. Being able to support early development stages of R&D and prototypes without the cost of tooling or extensive set-up is also a benefit to using lasers. A major deciding factor however is the precision of laser manufacturing. With dimensional and profile accuracy surpassing other methods, laser cut parts offers significant value. Keep in mind that laser cutting is not only a process to support R&D and small trials, but laser manufacturing is a proven solution as a high volume supply stream partner. The final choice relies on the factors that envelop each project and weighing the positives and challenges.