Laser Cut Phosphor Bronze Service

Trusted by

1,000’s

of Satisfied Customers

30+

Years in Business

With a combination of copper, tin, and phosphorus, the resulting alloy is a metal that is recognized for its strength, ductility, spring qualities, and include wear and corrosion resistance. Phosphor Bronze is the result and today it’s used in industrial precision applications for the electronics, marine industry, aerospace industry and other industries. Phosphor bronze stands out as a heritage alloy refined for the modern age. Today, advanced fabrication methods like laser cutting allow manufacturers to push the limits of precision cut phosphor bronze and support ongoing technological advances. Although laser cutting may be new for many seeking an option to produce needed components, laser cutting has been a great solution to many industries for decades now. To learn more about the phosphor bronze and laser cutting technology, the following questions and answers are provided.

Manufacturing Tolerances

What Are the Tightest Tolerances Your Laser Cutting Process Can Maintain When Cutting Phosphor Bronze?

When cutting phosphor bronze, our laser cutting process can maintain exceptionally tight tolerances, often within just a few thousandths of an inch. Thanks to the alloy’s fine grain structure and the precision of advanced laser systems, you will see tolerances held to +/- 1mil to +/- 2milsm depending on the geometry, thickness and laser system used. Unlike mechanical cutting methods, the laser’s non-contact beam minimizes distortion making it ideal for high-performance parts like electrical contacts, connectors, and precision springs where accuracy is critical.

Manufacturing Using Phosphor Bronze

How Does Laser Cutting Compare to Die-cutting, Waterjet, or CNC Machining of Phosphor Bronze?

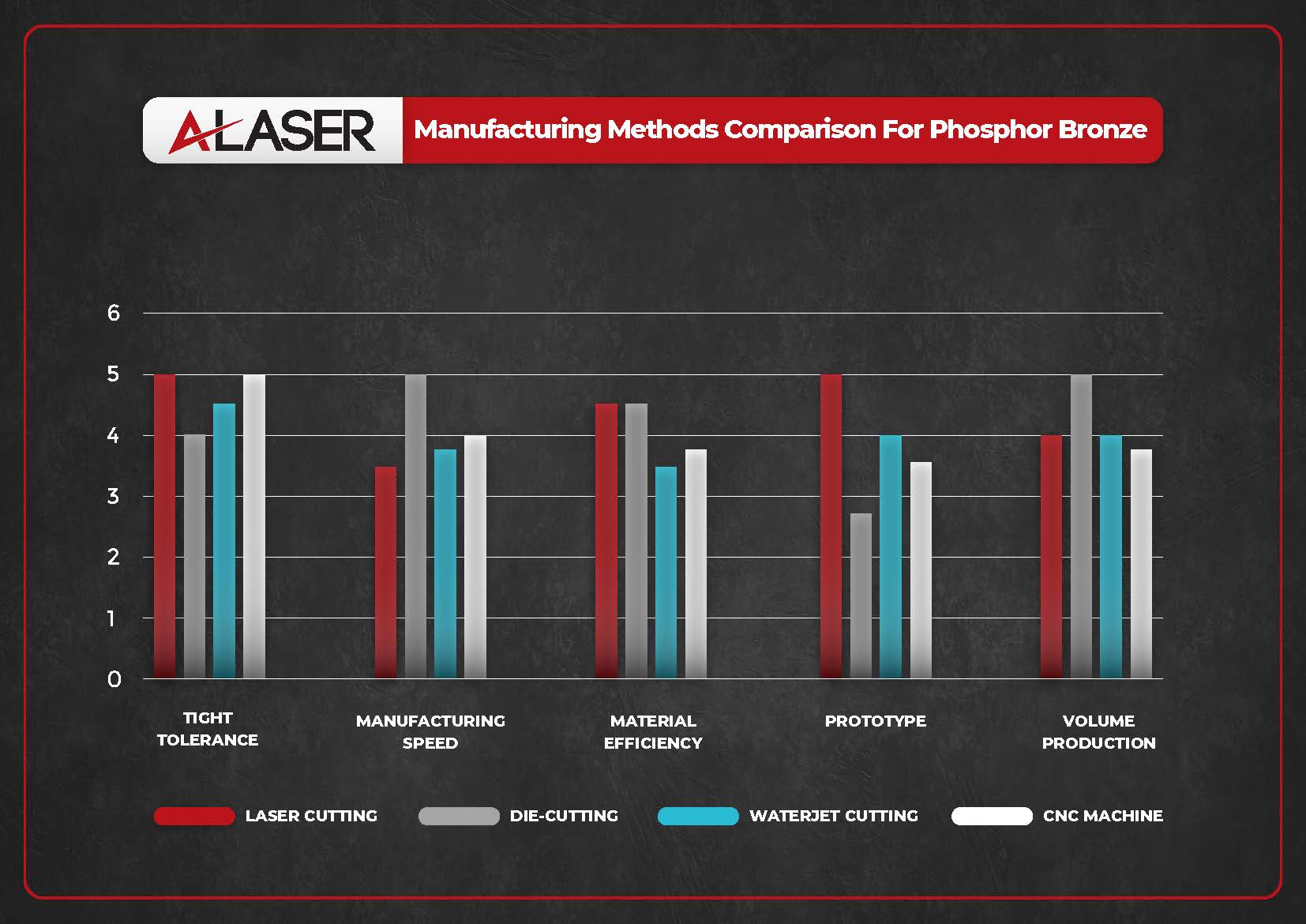

By selecting phosphor bronze to be laser cut, you can anticipate that the needed features and profile will incur precision and consistent quality. Laser cutting technology excels at this, but it is not the only player in manufacturing. Since projects are vastly different, so are the options available to produce high quality parts. The chart below is a comparison in manufacturing phosphor bronze components but is not a final conclusion to each manufacturing methods capabilities.

When precision projects come forward, we will review the details to confirm that our capabilities will support the requirements in both material and features. Each manufacturer will go through a similar process and if the conclusion is that a project is out any manufacturing capability, it is important that recommendations be made to customers on what technology may be best.

Controlling Material Characteristics

How Do Material Characteristics Like Reflectivity, Softness, or Thermal Conductivity Affect Edge Quality and Tolerance Control in Phosphor Bronze?

Phosphor bronze’s unique balance of reflectivity, softness, and thermal conductivity directly shapes the results of laser cutting. Its reflective surface can challenge some laser types, but advanced fiber and ultraviolet lasers overcome this to deliver clean, precise cuts. The alloy’s relative softness allows for smooth edges with minimal burrs, while its moderate thermal conductivity helps prevent excessive heat buildup that could distort delicate features. Together, these characteristics make phosphor bronze highly suitable for producing tight-tolerance components with consistently high edge quality.

Edge Quality Expectations

What Edge Quality Can Be Expected When Laser Cutting Phosphor Bronze? Are Burrs or Heat-Affected Zones (HAZ) Present?

- Clean, Precise Edges – Laser cutting produces sharp, well-defined edges on phosphor bronze, ideal for intricate parts.

- Minimal Burr Formation – Unlike mechanical cutting, burrs are very limited, reducing the need for secondary finishing.

- Controlled Heat Effects – Advanced lasers concentrate energy precisely, keeping heat-affected zones (HAZ) small and preserving the alloy’s spring and conductive qualities.

- Consistent Quality – From thin foils to thicker sheets, laser cutting delivers uniform results part after part.

- Ideal for Precision Components – The process supports the demanding edge quality required for connectors, contacts, and fine spring elements.

Concluding Remarks

What Are the Benefits of Laser Cutting Phosphor Bronze?

Laser cutting phosphor bronze offers the perfect mix of precision and reliability, making it a go-to choice for industries that demand accuracy and performance. The process delivers tight tolerances and smooth edges with minimal burrs, while carefully controlled heat input protects the material’s spring properties and conductivity. Unlike traditional cutting methods, lasers can handle intricate shapes without tool wear or distortion, ensuring consistent quality across every part. This makes laser cutting especially valuable for producing high-performance components like electrical contacts, precision springs, and connectors where both durability and fine detail matter.