Laser Cut Zinc Service

Trusted by

1,000’s

of Satisfied Customers

30+

Years in Business

Zinc metal alloy is commonly blended with other alloys such as aluminum, copper, and magnesium for enhanced strength, corrosion resistance, and dimensional stability. Zinc combined with copper creates brass, which is valued for its aesthetic appeal and ability to be formed and machined with good strength. Zinc and zinc-based alloys are made into components for industrial uses in automotive, electronics, consumer products, musical instruments and many more applications. Raw zinc, (Sphalerite) or zinc oxide ore, is extracted through complex processes. For high precision flat parts, zinc and its combination of alloys are laser cut into profiles that otherwise may not be possible using traditional methods. Further insight into zinc and laser cutting technology is provided with the following questions and answers.

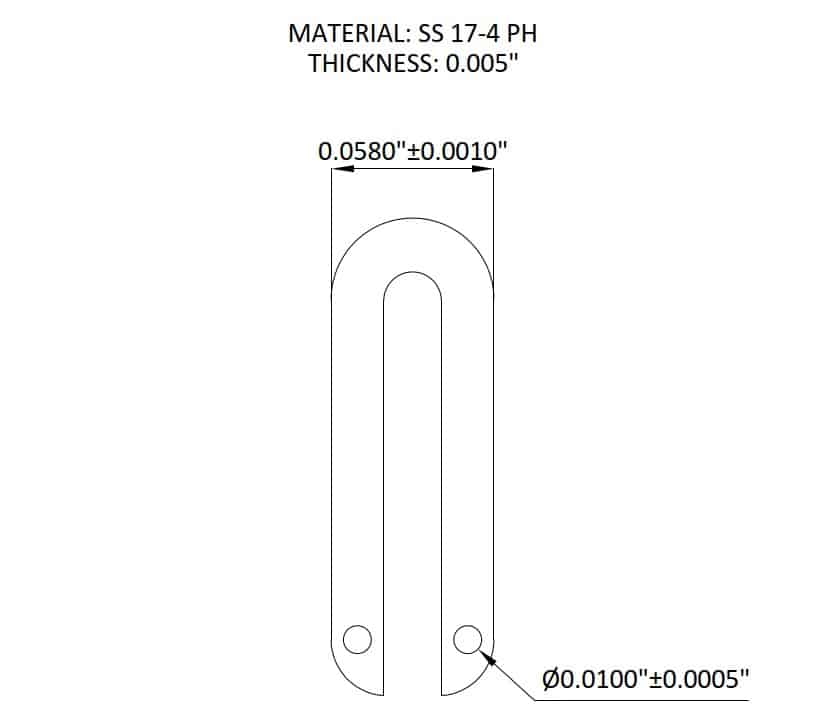

The Tale of Precision Tolerance

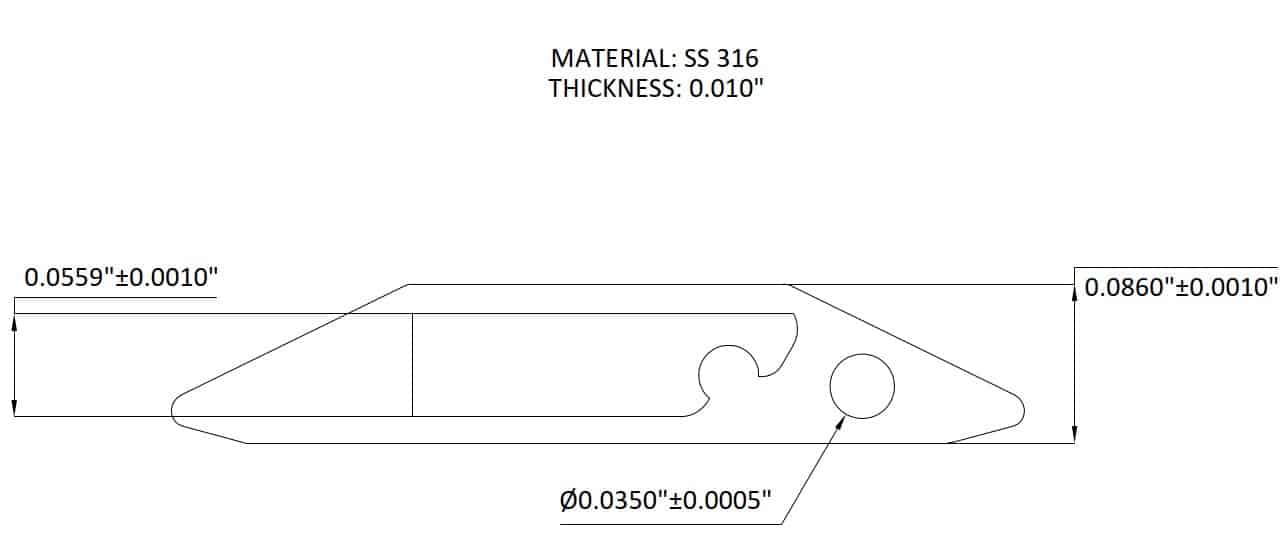

What Are the Tightest Tolerances Your Laser Cutting Process Can Maintain When Cutting Zinc?

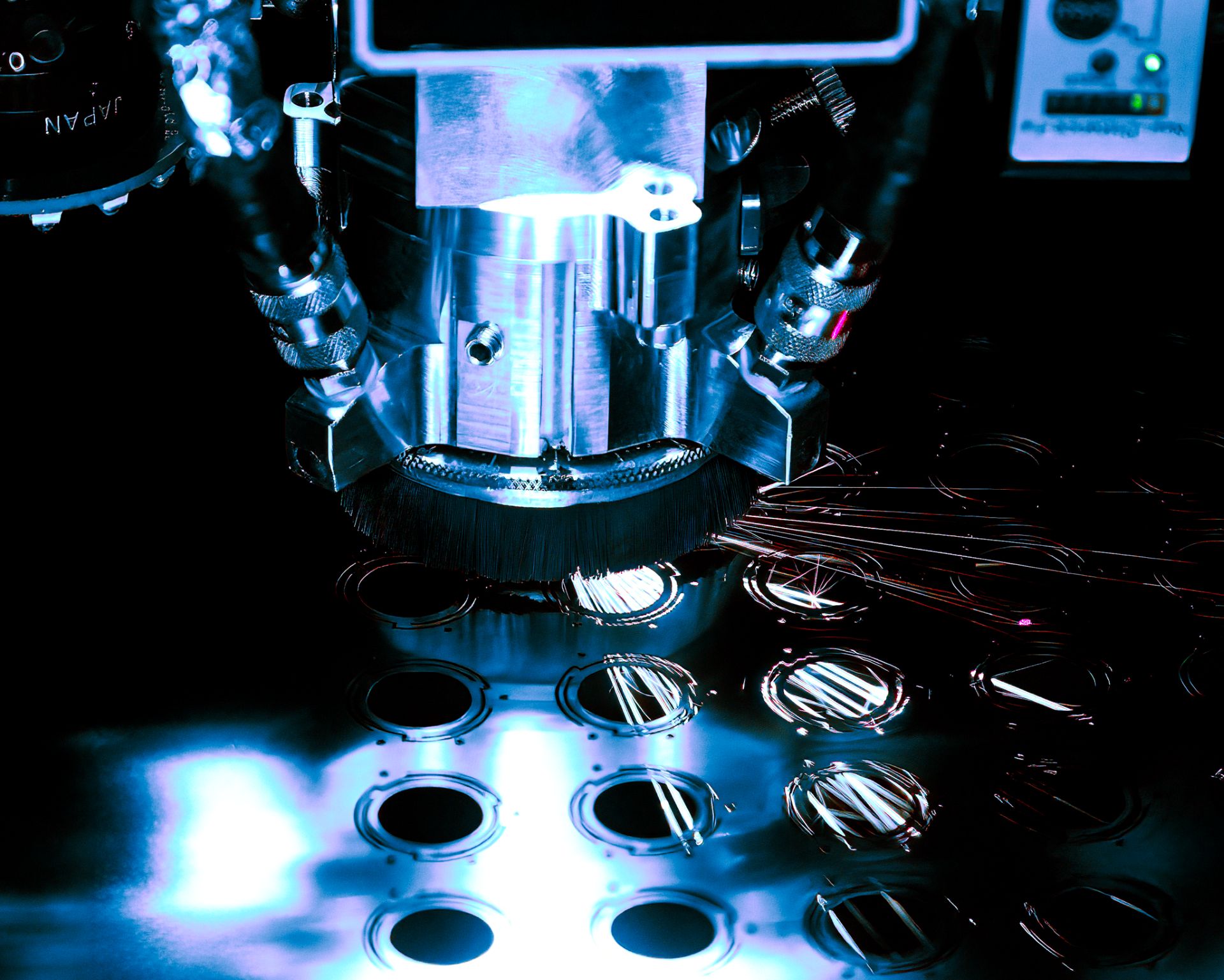

Control of tolerance is always a factor of considerable concern for customers that require consistent precision. Laser cutting specialists realize this and by using the appropriate laser system can provide reliable and high-quality components, with tolerances conforming to industry standards. For laser cut zinc, because it has a low melting point, attention to the laser parameters is needed to ensure the correct tolerance is achieved. Using a UV or ultraviolet laser for thin foils and sheets, you can expect a tolerance of +/- .5 mil to +/- 1 mil. For more complex designs or one larger in scale over 18” inches in x and Y, a tolerance of +/- 2 mils will be set.

How Zinc Can Be Cut

How Does Laser Cutting Compare to Die-cutting, Waterjet, or CNC Machining of Zinc?

Although laser cutting machines cut zinc and other metal alloys, there are always alternatives to manufacturing. The following comparison is a general look at processing zinc alloy, but not a conclusion of any method’s final capabilities:

Laser Cutting

- Excels at fine detail and intricate geometries, especially in thin zinc foils and sheets.

- Non-contact method → no tool wear, distortion, or mechanical stress on delicate parts.

- Heat management is critical due to zinc’s low melting point, but UV or pulsed lasers minimize this.

- Ideal for prototyping and low-to-medium runs since no tooling is required.

Waterjet Cutting

- Cold process with no heat-affected zone (HAZ) or risk of zinc vaporization.

- Capable of cutting thicker zinc stock with consistent results.

- However, kerf width is larger, tolerances are looser, and edges may require secondary finishing.

- Slower for very small or detailed parts compared to laser cutting.

Die-Cutting

- Efficient for high-volume production, but requires custom tooling, adding cost and lead time.

- Limited in handling very fine, complex shapes compared to lasers.

- Mechanical processes can introduce burrs, deformation, or tool wear, especially with softer zinc alloys.

CNC Machining

- Offers excellent dimensional control and surface finish, especially for thicker or 3D zinc parts.

- More material waste due to subtractive nature.

- Slower flat, thin geometries where laser cutting is more efficient.

- Requires tool changes and maintenance; softer zinc alloys may cause galling or tool clogging.

Laser cutting stands out for precision, flexibility, and speed in thin, flat zinc components, while die-cutting dominates in mass production, waterjet is best for thick stock without heat effects, and CNC machining is most valuable when 3D shaping, or deep milling is required.

Zinc Attributes

How Do Material Characteristics Like Reflectivity, Softness, or Thermal Conductivity Affect Edge Quality and Tolerance Control in Zinc?

When laser cutting zinc, its natural traits like reflectivity, softness, and high thermal conductivity play a direct role in determining edge quality and precision. Reflectivity challenges infrared lasers, but UV wavelengths improve absorption and stability. Softness allows for tight tolerances but can introduce burrs if molten metal isn’t managed and high thermal conductivity spreads heat quickly, requiring carefully tuned parameters to maintain clean, narrow kerfs. The following table offers more information:

| Material Trail | Impact On Edge Quality | Impact On Tolerance Control | Insight |

|---|---|---|---|

| Reflectivity | Reflects infrared wavelengths (CO₂, fiber lasers), which can cause unstable cuts or incomplete penetration. | Parameters such as beam focus, power, and wavelength must be carefully optimized. | Use of shorter wavelengths (UV lasers) improves absorption and delivers cleaner, more reliable cuts. |

| Softness (low hardness) | Edges can be prone to burrs or smearing if molten zinc solidifies unevenly. | Very tight tolerances possible in thin sheets, but soft surfaces may show micro-deformation if heat isn’t well controlled. | Non-contact cutting avoids tool pressure, giving lasers an edge over stamping or machining. |

| Thermal Conductivity (high) | Heat dissipates rapidly, reducing local melting but also making it harder to maintain a narrow, consistent cut line. | Can cause variability in kerf width or edge taper if laser parameters aren’t matched to sheet thickness. | Pulsed lasers or higher scan speeds help balance heat input, preserving precision. |

With the right laser technology and settings, these traits can be harnessed rather than hindered, delivering sharp edges and consistent tolerances well-suited for precision components.

Laser Cut Edge Quality

What Edge Quality Can Be Expected When Laser Cutting Zinc? Are Burrs or Heat-Affected Zones (HAZ) Present?

Laser cutting zinc can achieve clean, precise edges with minimal post-processing when the process is carefully controlled. However, due to Zinc’s low melting point and high thermal conductivity, some minor burrs or dross may form if heat input is excessive. Heat-affected zones (HAZ) are typically shallow and localized, especially when UV or pulsed lasers are used, preserving material integrity. With experienced laser service providers, the result is sharp, consistent edges suitable for precision components, with only limited finishing required in most cases.

Key Takeaways

What Are the Benefits of Laser Cutting Zinc?

The benefits of laser cutting zinc lie in its ability to produce highly precise, intricate shapes without the need for tooling, making it ideal for prototypes, low-to-medium production runs, and complex designs. Laser cutting avoids mechanical stress and tool wear, while delivering consistent, repeatable results with smooth edges that often require little finishing. Lasers offer greater flexibility in design, faster turnaround, and the capability to work effectively with thin foils and sheets, compared to traditional methods. This is a smart choice for manufacturers seeking both accuracy and efficiency in zinc components.