Laser Cutting Tin Service

Rare and challenging alloys like tin alloys are being made into precision parts with laser cutting machines. Tin has a history that stretches back over 5,000 years, famously alloyed with copper to create bronze and form the Bronze Age. In today’s manufacturing landscape, tin and tin-based alloys benefit from advanced fabrication techniques like laser cutting, where the precision, minimal heat distortion, and clean edges of laser processing allow engineers to achieve intricate geometries and tight tolerances impossible with traditional methods. For further insight into tin, the following questions and answers are provided.

Controlling Tolerance

What Are the Tightest Tolerances Your Laser Cutting Process Can Maintain When Cutting Tin Metal Alloy?

Laser cutting is accurate in cutting tin metal alloys, we can hold tolerances down to about +/- 1mil. That means the final part will be true to size within a thickness of a human hair—or even finer. This level of precision comes from the laser’s ability to concentrate heat into a tiny spot, melt only what’s necessary, and move with digitally controlled positioning systems that don’t waver or drift. If your design calls for razor-sharp accuracy, the laser can deliver it, every time, without the mess or variability of more traditional cutting methods.

Choosing Between Technologies

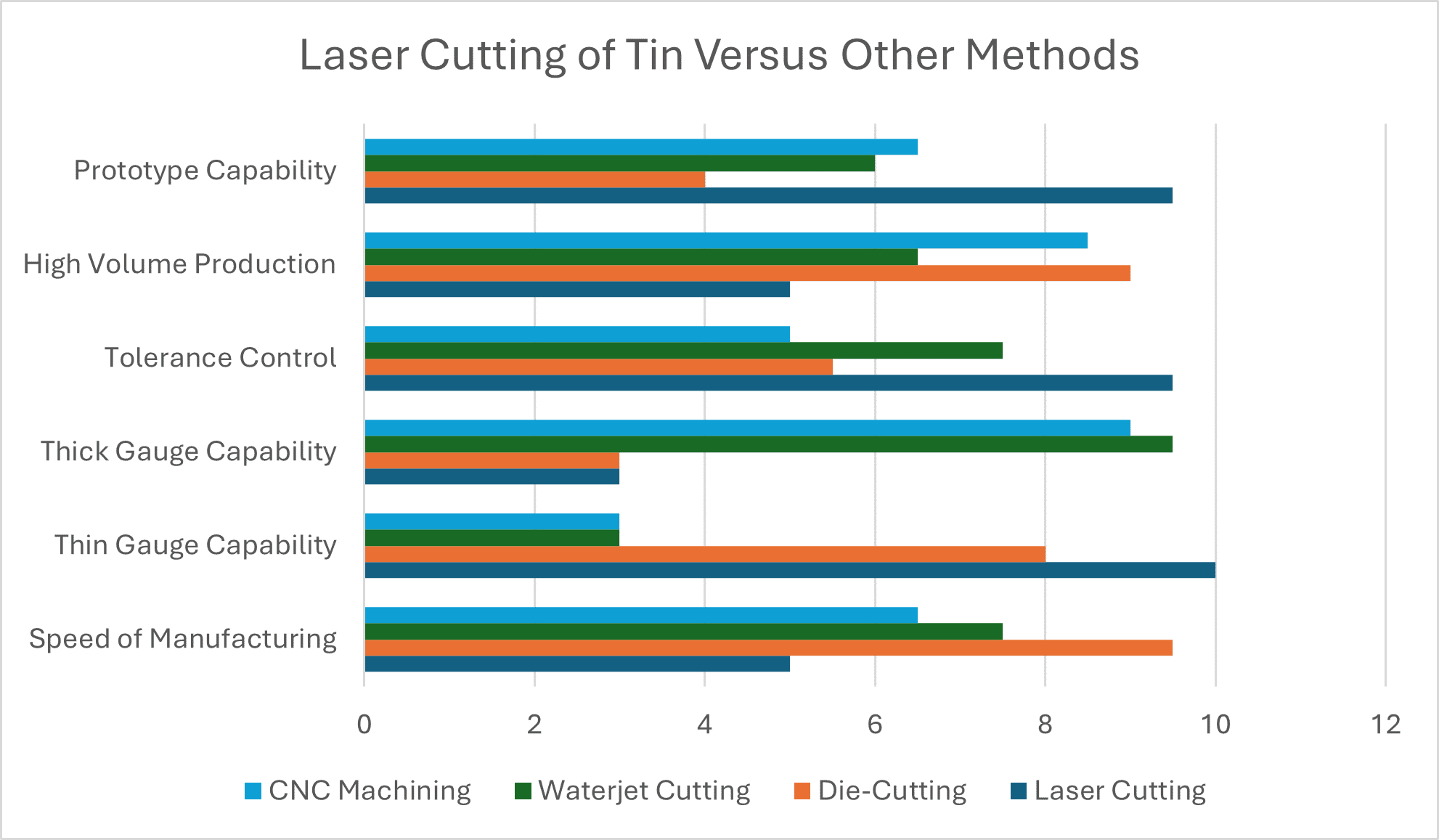

How Does Laser Cutting Tin Compare to Die-Cutting, Waterjet, or CNC Machining of Tin?

The following methods all have great characteristics and capabilities in manufacturing components. They are tried and true and used for many of the same industries by focusing on what they do best. There is no best methodology, rather this comparison focuses only on manufacturing of precision components from tin metal alloy.

Laser Edge Quality

What Edge Quality Can Be Expected When Laser Cutting Tin and Are Burrs or Heat-Affected Zones (HAZ) Present?

Laser cutting has a reputation for manufacturing flat parts that in edge quality that is clean, smooth, and dimensionally true. There is no ragged tearing, no chatter marks, just a sharp, well-defined profile. Because the laser’s heat is concentrated into an incredibly small area, burrs are minimal to nonexistent. Control of the laser parameters is the key to achieving optimum edge quality. As for the heat-affected zone (HAZ), it’s very small, often just a hairline band at the cut edge, and with the right parameters, it won’t alter the alloy’s properties or cause discoloration.

Material Characteristic Factors

How Do Material Characteristics Like Reflectivity, Softness, or Thermal Conductivity Affect Edge Quality and Tolerance Control in Tin?

Raw tin is rarely used in manufacturing, but you find tin being used to form alloys like bronze, phosphor bronze, pewter, and in tin solder alloys. Cutting tin alloys can be challenging to maintain edge quality.

| Material Characteristics | Affect On Edge Quality | Affect On Tolerance Control |

|---|---|---|

| Reflectivity | Tin has a shiny, reflective surface, which can bounce some of the laser’s energy away, affecting edge quality. | Laser parameters need adjustment of focus and energy. Inconsistent cuts can result if not done correctly. |

| Softness | Tin is relatively soft compared to many metals, so it doesn’t resist the cut. This is great for maintaining sharp edges. | The cut speed, power need to be balanced to prevent slight deformation or edge round edges and potentially hinder tolerance. |

| Thermal Conductivity | The right beam focus speed, laser passes, you can keep that heat contained, producing edges that are clean, precise, and true to your design. | Tin conducts heat quite well, if not controlled, this could widen the heat-affected zone. |

So, the material’s natural characteristics doesn’t limit the laser, but it does mean the laser parameters will have to be adjusted to hold tight tolerances with edge quality at a premium.

The Payoff

What Are the Benefits to Laser Cutting Tin?

Laser cutting is a great way to produce some extremely fine and precise profiles because it is a non-contact process with no tool wear and no mechanical stress. Parts made are not distorted from clamping, making it perfect for thin or delicate tin components. The flexibility to switch from one design to another is as easy as loading a new file, without creating costly dies or tooling. Lasers can be efficient in cutting materials and designs that other methods have difficulty with. Efficiency in material usage to nest parts tightly on a sheet makes it both cost-effective and material smart. In short, laser cutting turns tin alloy from “just a metal” into a precision-crafted component ready for modern, high-performance applications.