Laser Technologies

Laser cutting technology has taken the precision parts industry to new levels, enabling increased complexity in design, higher cut quality and the ability to maintain tighter tolerances through laser ablation.

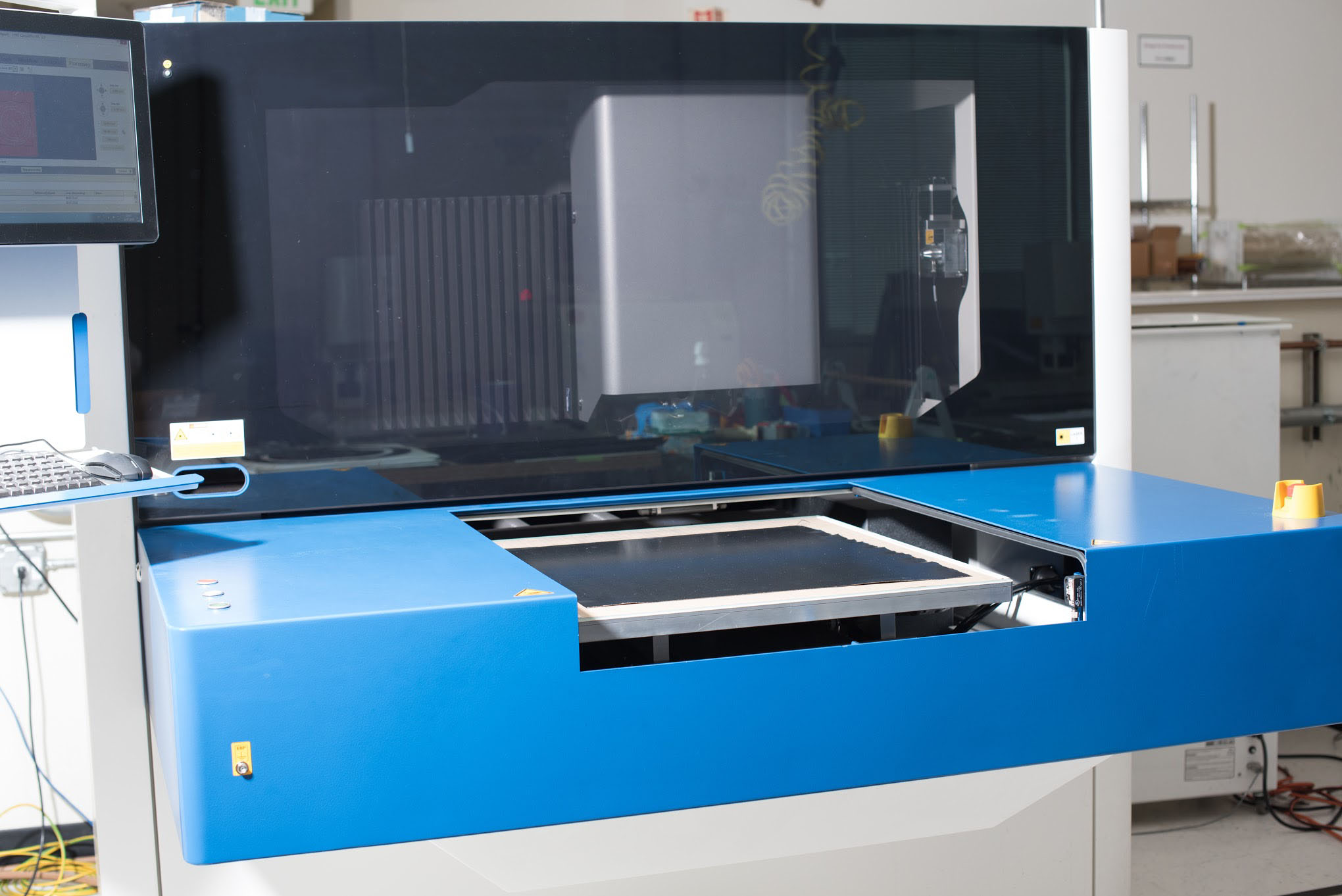

Ultra Violet (UV) Lasers

Laser ablation in the UV frequency produces incredibly fine features, precisely cut, and with minimal thermal influence or carbon residue. These systems are mainly used for the production of non-metal parts, but we’ve also achieved results with ultra-thin metal parts.

- Microline 600 LPKF lasers

- Frequency-tripled NdYag diode-pumped

- 20-micron beam

- Pulse repetition rates up to 250 kHz

- 355-nanometer wavelength

- Pulse length <100 nanoseconds

- Contact-free laser ablation ensures material integrity

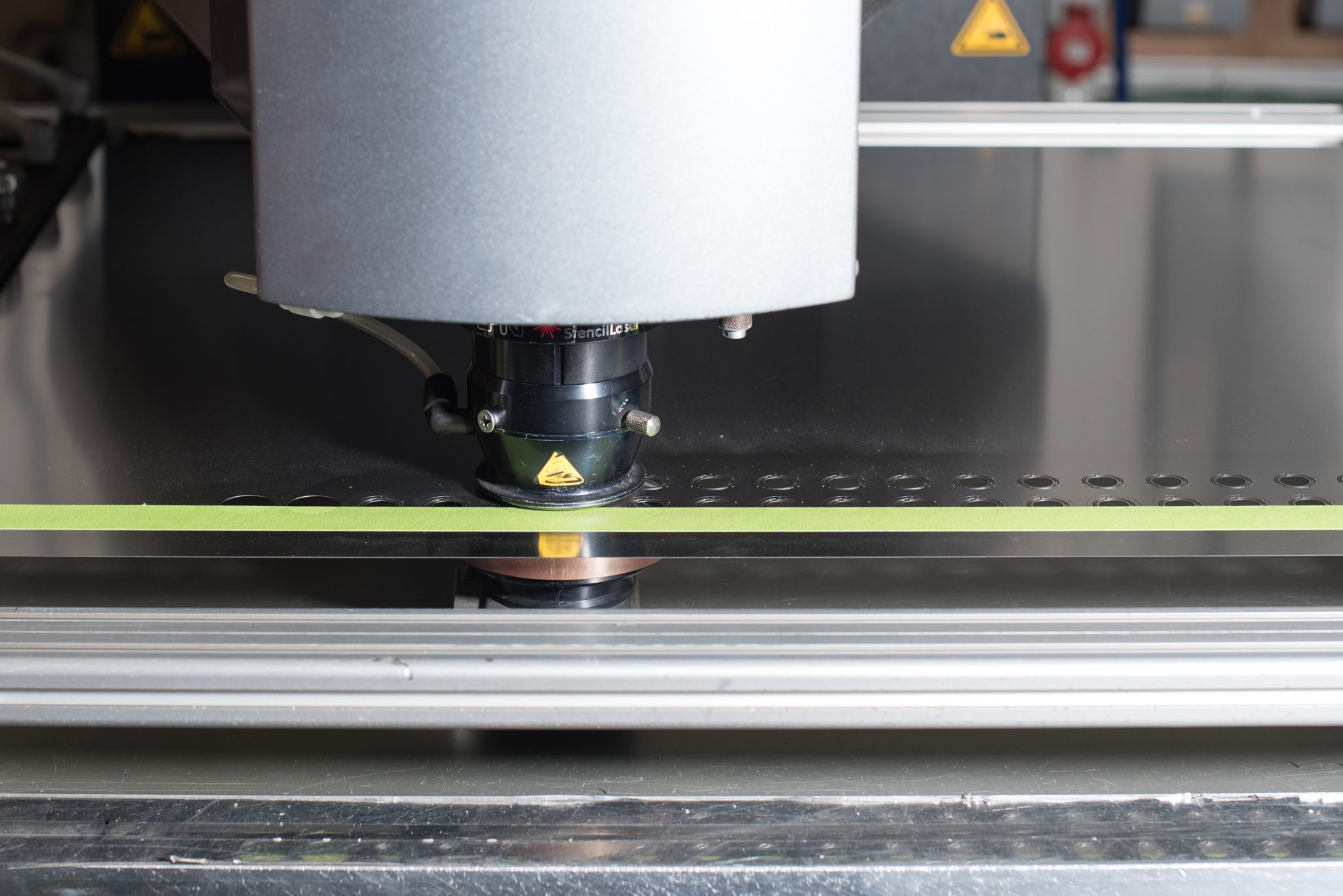

Infrared (IR) Lasers

Our IR laser systems have one of the most stable motion systems in the world. The result is a clean, burr-free cut that is exactly where your application demands. The IR laser beam diameter is so small that the most intricate designs become possible.

- LPKF 1065 nm diode pumped NdYag

- Contact-free processing, therefore no material distortion

- <40-micron beam for fine features

- +/-.0005″ tolerance repeatability

- 001″ – 0.025″ metal thickness range