Transforming Your Ideas into Tangible Realities with the Magic of Laser Cutting

Custom laser cut prototypes are a unique method of transforming new ideas into precision components and parts for countless applications. Prototyping can be frustrating with endless iterations, and designs that just don’t meet your requirements for precision. When traditional methods just don’t cut it (pun intended!), you need precision that thrills. Laser cutting technology is a method for manufacturing prototypes and productions runs that has set itself apart from other manufacturing sectors. Not to say that methods like stamping, die-cutting, waterjet cutting, or CNC machining are not great, they are and indeed have tremendous value to manufacturing. However, laser cutting is a premium supplier supporting prototyping of flat precision geometries that other methods cannot match.

The Benefits Are a Cut Above the Rest

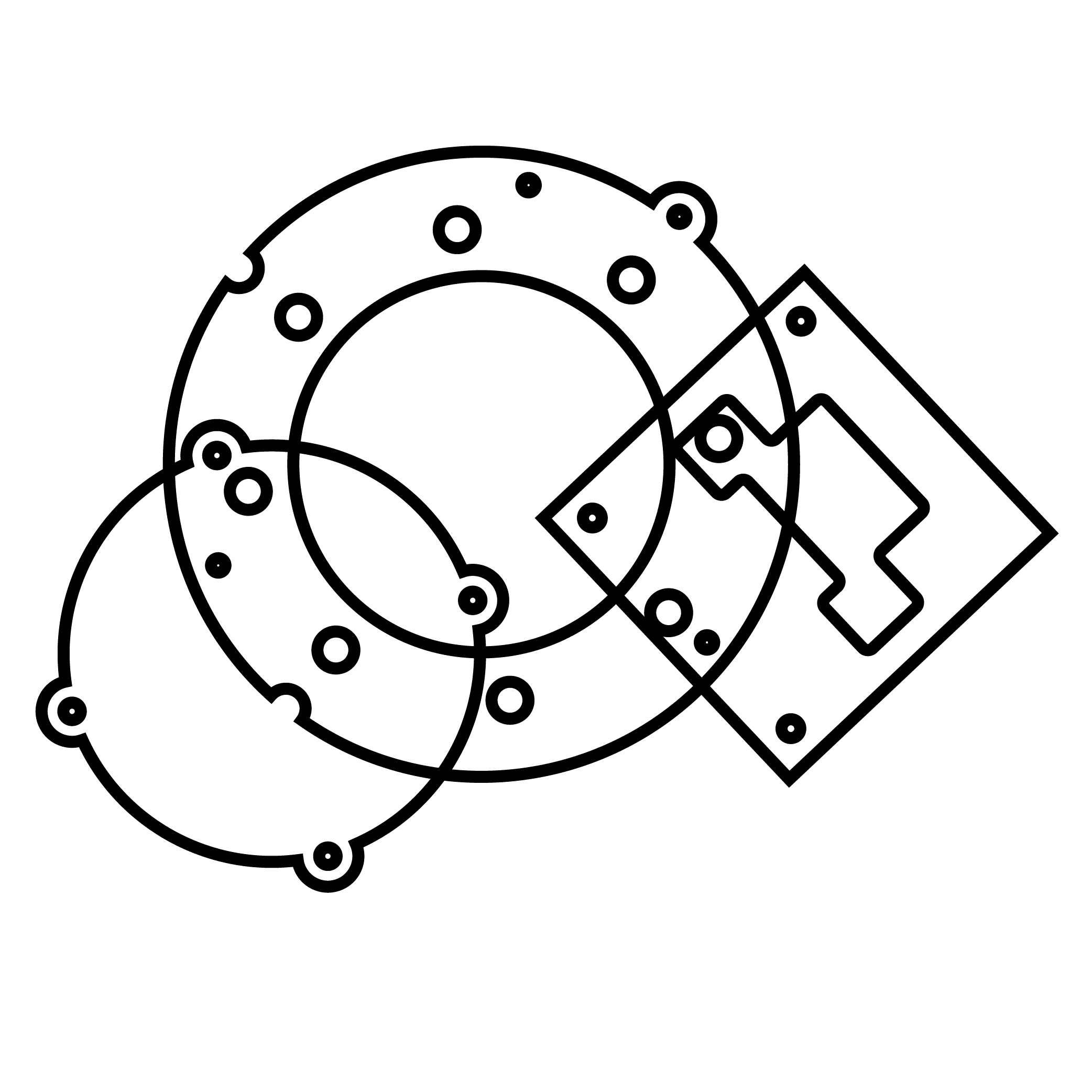

For flat 2D geometries, laser-cut prototypes offer several key benefits over other manufacturing methods:

- Exceptional Precision: Achieve extremely tight tolerance and intricate details that are often difficult or impossible with traditional cutting methods. Standard tolerances can be +/- 0.0254mm.

- High Speed: Rapid turnaround from design to physical prototype, significantly accelerating development cycles. Most laser cut projects do not require tooling or extensive set-up.

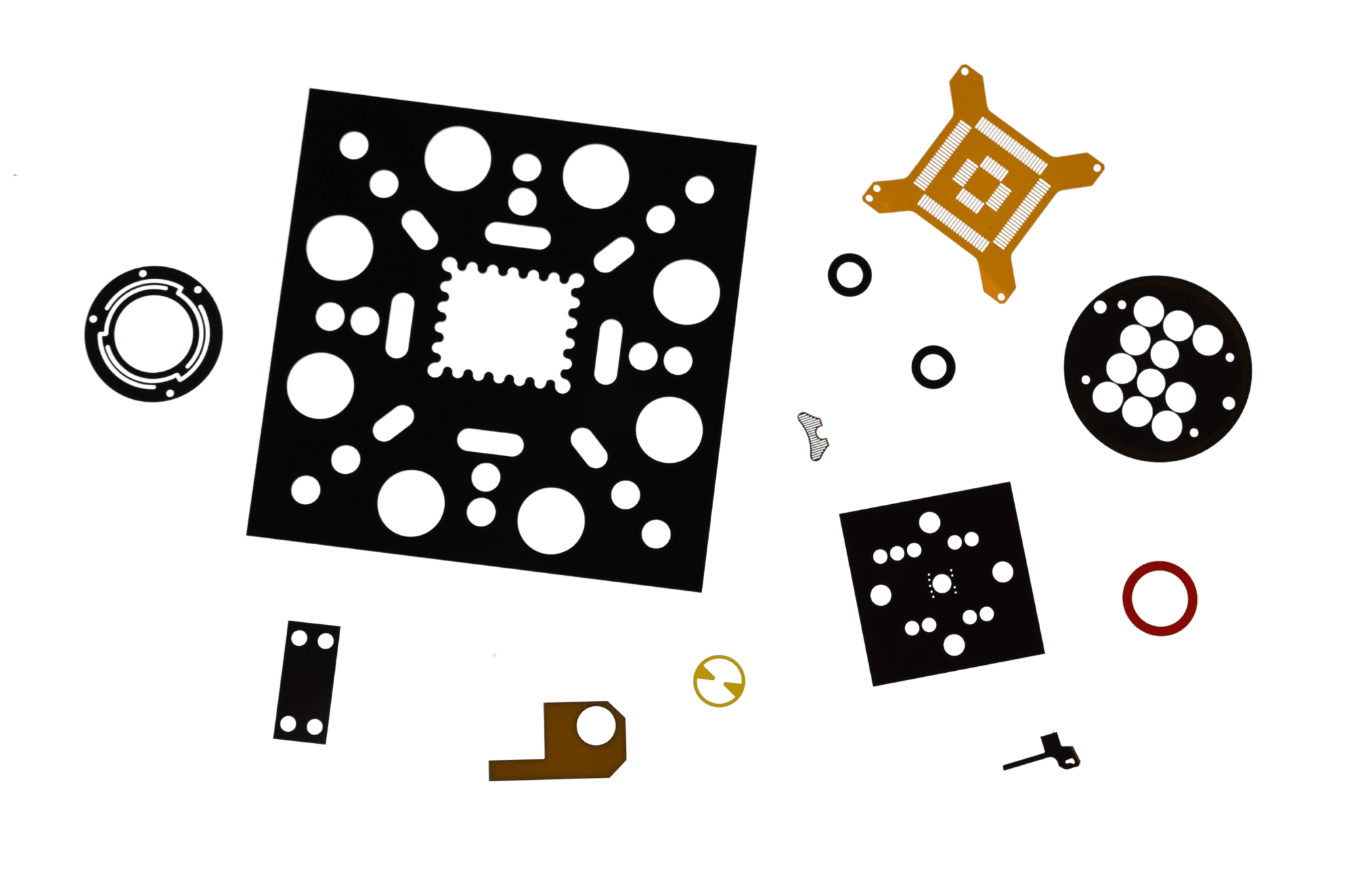

- Material Versatility: Capability to process a wide range of materials, including various polymers, (Kapton, PEEK), FR4, Metal alloys like nickel, brass, aluminum, stainless steel, titanium, nitinol, grafoil, alumina ceramic, silicon rubber, nitrile rubber, adhesives, and many more.

- Cost-Effectiveness: Multiple iterations can be cut at the same time. This makes prototyping more affordable for small batches and one-off prototypes due to minimal tooling costs and quick setup times.

- Design Flexibility: With laser technology, the two main ingredients are materials and CAD data. Easy handling of complex features and profile cuts without the need for specialized tools for each design. CAD (dxf, dwg, STEP, Vector, or Gerber) will be the path that the laser is programmed too. With fine-tuned adjustments to the selected material and thickness, the data is cut into the prototype.

Getting to the prototyping phase is a major step and can determine if the project will move forward or need additional refinement. Laser cutting specialists work to achieve your goals and with the rapid pace can reduce the time of testing and evaluation.

Our Prototyping Process

Laser cutting can be detailed just as other methods in adjusting and fine tuning the parameters to achieve the desired results. Getting your project started is easy and it is exciting to know that ideas that have been designed can now be made into tangible components. The feel of the precision cut edges, and the measured accuracy of features are now a reality. Shown below are the basic steps to have your prototype made:

- The Spark-Your Brilliant Idea: Share your CAD files, sketches, or even just a detailed description. Early communication can also advise on material type and availability.

- The Magic of The Beam: The production team will review the specifics and determine what laser technology is best and the appropriate parameters needed to create the prototype.

- Quality confirmed and Accuracy Measured: OGPs (Optical Gaging Products) or similar inspection devices are paramount in producing qualified precision components.

- Prototype Perfection: The manufactured prototype will be of high quality and accurate. Once approved, laser cutting technology can transition from prototypes to production seamlessly as a qualified supplier to the production chain.

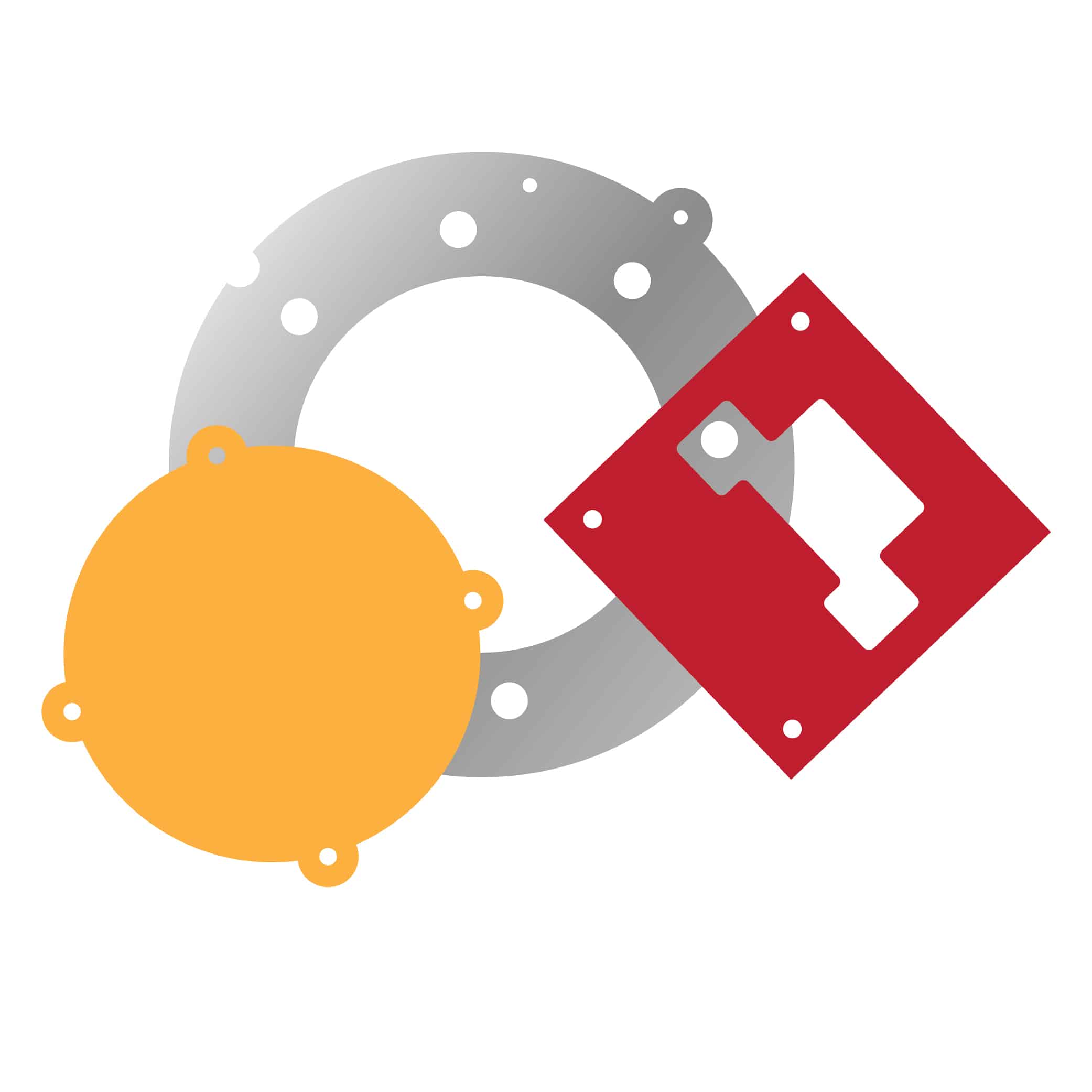

How these prototypes are applied can be just as interesting as the process. Custom laser cutting provides precision as a standard and by doing so, it reflects the industries using this technology to its highest potential. Let’s see where and how laser cut prototypes are exceling.

Real World Applications

Laser cutting technology is revolutionizing how industries bring new products to life, making rapid prototyping more accessible and efficient than ever. From the intricate gears of a cutting-edge robotics system to the delicate patterns in high fashion, the precision, speed, and versatility of laser-cut prototypes are unlocking unprecedented design possibilities across a diverse range of sectors, transforming visionary ideas into tangible realities such as:

- Electronics: Cutting prototype PCBs (Printed Circuit Boards), is a necessity to work out any issues and confirm the board and component’s function. Besides laser depaneling, prototypes can be done to remove solder mask to expose copper pads and vias.

- EV Battery Technology: Emerging technologies like EV Batteries is progressing rapidly with more efficient battery cells. Prototyping for components like busbars, insulators, tabs, and spacers are increasing in demand and made from nickel, copper, and polyimide.

- Textiles: Commercial textiles are made for use everywhere. Before production can ensue in lots of thousands of yards, smaller prototype runs are needed. Laser cutting produces these precision guides of stainless steel.

- Medical Research and Development: Medical diagnostics or components used in invasive surgical devices need prototypes. This long and arduous process relies on laser cutting to provide scalable prototypes.

- Semiconductor Development: Semiconductor chips are incredible in their technology and the manufacturing processes that are involved. To continue advancing more powerful and efficient chips, laser cutting of prototypes for gaskets and shims in processing equipment is fast paced and requires the highest quality standards.

Conclusion

Challenges are a given in laser manufacturing and by providing custom laser cut prototypes that meet specification of rapid turn times, material flexibility and precision, the reward for laser manufacturing specialists is a recurring and solid partnership with industries. Stop dreaming about your next big idea and start holding it in your hands. Let’s make something amazing together.