PEEK Material

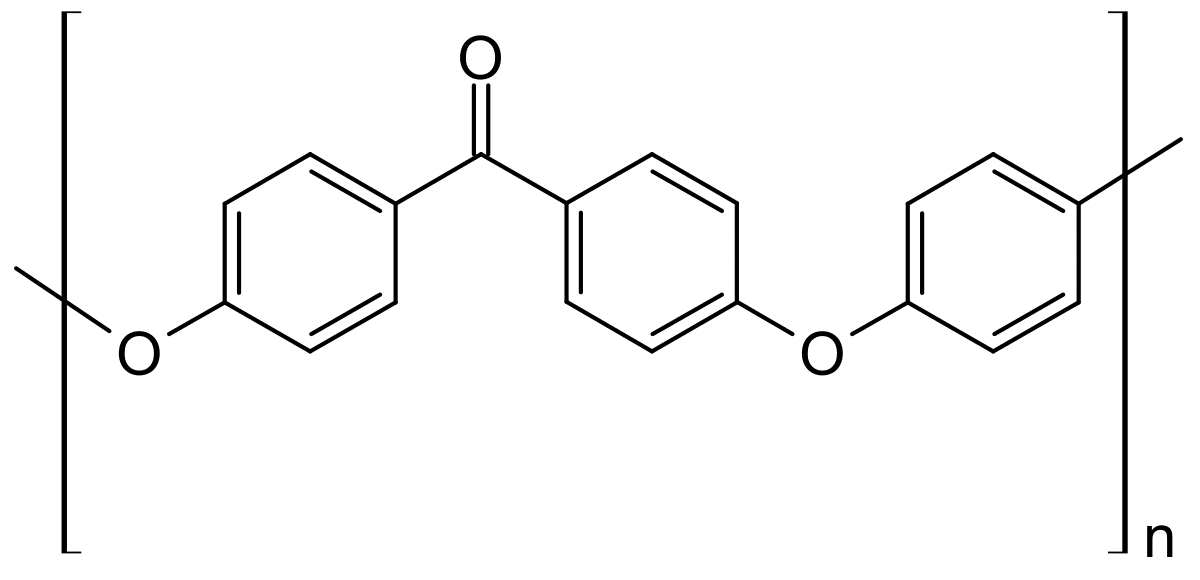

What Is PEEK Material?

PEEK is a semicrystalline thermoplastic that stands out for its unique balance of properties:

- High Thermal Stability: PEEK retains its strength and dimensional stability at temperatures up to 260°C (500°F).

- Chemical Resistance: Resistant to a wide range of chemicals, including acids, bases, and organic solvents.

- Mechanical Strength: Offers excellent tensile and flexural strength, even under harsh conditions.

- Biocompatibility: Frequently used in medical implants and devices due to its compatibility with the human body.

These attributes make PEEK an excellent choice for applications requiring durability, precision, and reliability.

Applications of PEEK Material

PEEK’s versatility allows it to excel in numerous industries:

- Aerospace: Lightweight yet strong components for aircraft and spacecraft.

- Medical: Surgical instruments, dental implants, and orthopedic devices.

- Electronics: Insulators, connectors, and other components requiring high dielectric strength.

- Automotive: Bearings, seals, and other parts subjected to high temperatures and friction.

Laser Cut PEEK in the Medical Device Industry

PEEK’s role in the medical device industry is transformative, offering biocompatibility, durability, and resistance to high temperatures and chemicals. It’s commonly used in spinal implants, trauma fixation devices, and prosthetics due to its ability to mimic the flexibility and strength of human bone. With laser cutting, PEEK components can be manufactured with precision, enabling intricate designs and exact tolerances critical for lifesaving medical applications. This technology allows for the creation of tailored solutions that seamlessly integrate into the human body, exemplifying innovation in healthcare. This precision is vital for applications like custom surgical guides, microfluidic devices, and implantable sensors, where even the smallest detail can impact patient outcomes. By combining the advanced properties of PEEK with the accuracy of laser cutting, manufacturers can produce medical devices that push the boundaries of what’s possible in modern healthcare, ultimately saving and improving lives.

Ready to Work With PEEK?

If your project demands the precision and performance that only PEEK can provide, A-Laser is here to help. Our cutting-edge laser technology and expert team ensure your components are crafted to perfection. Contact us today to discuss your project and discover how we can bring your vision to life.