Kapton Sheets Precision Laser Cutting for Complex Designs

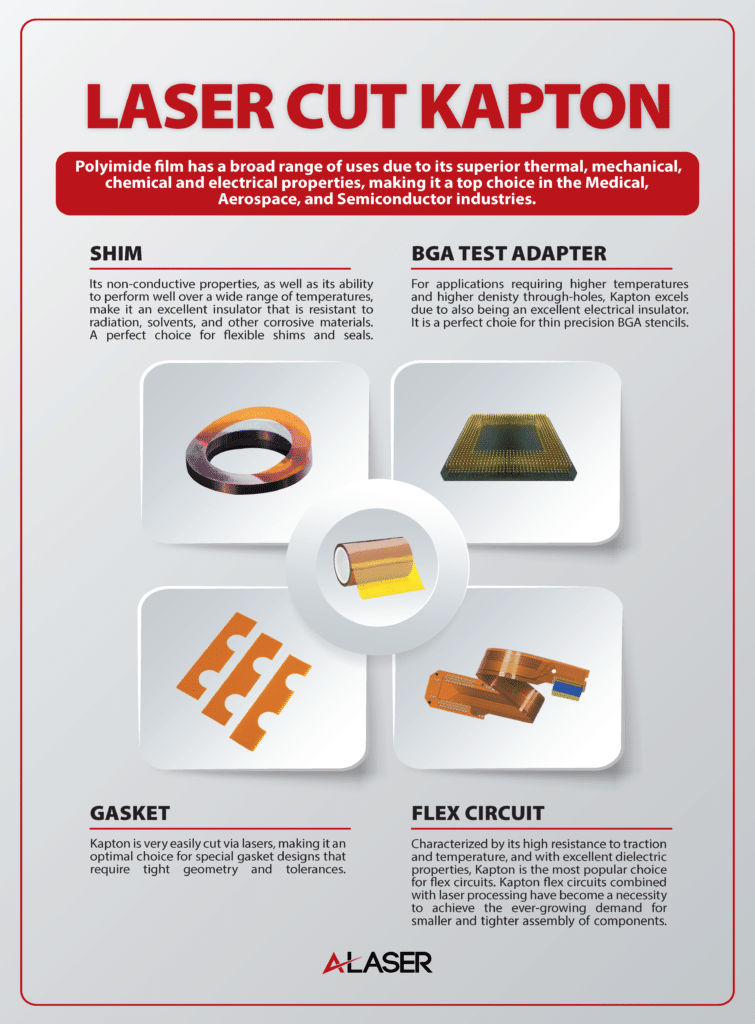

Kapton sheets, known for their exceptional thermal, chemical, and electrical insulation properties, are a go-to material for industries that demand high-performance and reliability. From aerospace to electronics, Kapton’s unique properties make it indispensable for creating flexible circuits, thermal barriers, and lightweight insulation. But working with this advanced material requires expertise—especially when precision and tight tolerances are essential for your designs.

At A-Laser, we specialize in laser cutting Kapton sheets, offering unparalleled accuracy and clean cuts for even the most complex designs. With years of experience processing this material, we are your trusted resource for transforming Kapton sheets into precisely crafted components tailored to your specifications.

What is a Kapton Sheet?

Kapton is a polyimide film developed by DuPont, prized for its ability to withstand extreme temperatures (-269°C to +400°C) without losing its mechanical properties. It is lightweight, highly flexible, and resistant to chemicals, making it suitable for demanding applications like:

- Flexible Printed Circuit Boards (PCBs): A common base material for electronics.

- Thermal Insulation: Used in aerospace and automotive industries.

- Optical Films: Ideal for applications requiring transparency and stability.

Kapton sheets are available in various thicknesses, from ultra-thin films for electronics to thicker grades for structural applications.

Why Laser Cutting is Ideal for Kapton Sheets

Kapton sheets require precise processing to maintain their unique properties, and laser cutting offers the clean, consistent results needed for high-performance applications. Here’s why laser cutting stands out:

1. Non-Contact Processing

Laser cutting eliminates mechanical stress that can cause tearing or deformation in Kapton sheets, preserving their structural integrity.

2. Extreme Precision

Our lasers achieve tolerances within microns, ensuring that every cut matches the exact dimensions of your design.

3. No Material Damage

Kapton’s high heat resistance allows for sharp, burr-free edges without burning, discoloration, or compromising the material’s properties.

4. Complex Designs Made Simple

From intricate patterns to micro-sized components, laser cutting handles complexity effortlessly, meeting the demands of industries like aerospace and electronics.

Designing for Laser Cut Kapton Sheets

| Aspect | Details |

|---|---|

| Material Properties | - Thermal stability (-269°C to +400°C) - Excellent electrical insulation - Chemically resistant to solvents and oils |

| Available Thicknesses | 0.001” to 0.010” (common for laser cutting applications). Custom thicknesses available upon sourcing. |

| Cutting Precision | Achieves tolerances as tight as ±0.001”. |

| Edge Quality | Burr-free, smooth edges, ideal for sensitive applications like electronics and medical devices. |

| Applications | - Flexible Printed Circuits (FPCs) - Insulation layers - Custom gaskets and spacers |

| Design Considerations | - Specify thickness and tolerances for accurate results - Incorporate complex geometries confidently, thanks to laser precision |

| Cutting Speed | Fast, efficient process that minimizes lead time compared to traditional methods. |

| Non-Contact Benefits | Prevents warping, tearing, or distortion of the material during cutting. |

| Post-Cut Readiness | Parts are cut cleanly and require minimal to no post-processing. |

| Environmental Impact | Produces minimal waste compared to traditional methods, aligning with eco-friendly manufacturing practices. |

The A-Laser Advantage for Kapton Sheet Cutting

While we don’t sell Kapton sheets, we maintain a stock for laser cutting projects and can source sheets to match your requirements. Our team of experts works closely with you to:

- Select the right Kapton sheet grade for your project.

- Optimize laser cutting settings for maximum precision and material efficiency.

- Provide rapid prototyping and production services to streamline your process.

Common Questions About Kapton Sheets

- Can Kapton sheets be laser cut without damaging the material?

Yes! Kapton’s high heat resistance makes it ideal for laser cutting. Our advanced lasers deliver clean cuts without scorching or deformation. - What industries commonly use Kapton sheets?

Kapton sheets are widely used in electronics, aerospace, automotive, and medical industries due to their insulation, flexibility, and durability. - What thicknesses of Kapton sheets can A-Laser process?

We can laser cut all ranges of Kapton sheets ranging with consistent precision across all thicknesses.

Contact Us for Kapton Sheet Laser Cutting

When accuracy, cleanliness, and reliability matter, A-Laser delivers unmatched expertise in cutting Kapton sheets. Whether you need a single prototype or high-volume production, we’re equipped to bring your designs to life with precision and care.

Reach out to discuss your Kapton sheet project today!