Laser Cut Projects

What Is a Laser Cut Project?

Laser cut projects produce so many fascinating precision components for high tech industries to small manufacturing businesses. They support new ideas to solve problems by being a conduit for start-up companies. Laser cut projects can be the bridge from prototypes to full volume manufacturing. It is unique opportunity that laser service providers have by working with individuals and companies in numerous outlets of technology. But what really is a laser cut project? In simple form a laser cut project is a creation where a laser beam is used to cut, engrave, or mark materials like metal alloys such as titanium, aluminum and stainless steel, to polyimides, ceramics and many other types of materials. Laser cut projects are not defined just by the materials used but also by the design features they can cut, which can be simple shapes to extremely complex geometries.

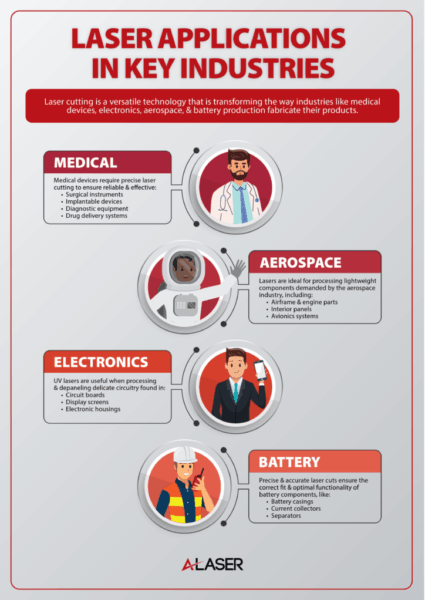

Laser manufacturing has been in growing demand since the late 1970’s but had its start in the early 1960’s. New methods were needed to continue the advancing industries and materials. To further explore why some projects are best processed by laser technology is to learn by example. The following list highlights some great examples of industries working together with laser technology service providers by harnessing the unique capabilities of laser technology.

The Range of Laser Cut Projects

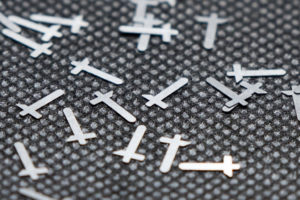

Medical Device Development: The medical industry has a tremendous impact on our lives and with such a high degree of responsibility to the end user. Rapid changes in all fields of medicine depend on new advances in technology. One of these was in cardiac care. A company called Cardica, was developing a new system of stapling arteries for heart surgery. This was innovative and required precision stainless steel parts to be made in thicknesses of .005” mils to .015” mils thick. Together they formed the mechanism in which tiny staples would be chambered. The tolerances were tight from +/- 0.0254mm to 0.0508mm. Laser technology supported this through ultraviolet, infrared and fiber laser systems to produce rapid iterations, high quality, and repeatability.

University Research: The main goal of a university is to educate and encourage new ideas, that get contemporary thoughts, out of the box. It supports new scientists and engineers to bring their ideas forth. One such example that led to a laser cut project was from Stanford University. The project required precise cutting of solar wafers developed by the Stanford Research Solar Team. The configuration of the cells needed accuracy at a +/- 0.0508mm and no damage. Ultraviolet laser technology was used for it non-contact method and the ability to hold the tolerance. The cells would be used on a solar powered car, that too was going to be run in a race. The transition of R&D to larger quantities was another key point in choosing laser technology.

The Aerospace Industry: Communications and radar sensors are a large part of the operating equation for all aircraft and especially commercial airlines. When a top airline company was designing and testing a new antenna system it required a gasket to be made that would seal the device. The required sealing material was a two-stage epoxy. This was tried on die cutting but failed because the epoxy was extremely soft and pliable. Though the tolerance was fairly large at +/- 0.203mm, the delicate nature of the epoxy required a non-contact solution which laser cutting provides. Using a ultraviolet laser at about 11 watts of power the delicate profile of the large gaskets, that were about 36” inches long at a width of about 4mm, were cut. A new process had to be developed for the cutting, handling and storage of the epoxy gaskets.

Wireless Energy: The use of wireless energy is increasing and is something we experience now, but it has limitations. As research grows to expand this range of power and applications, new technology is needed. A company called Ubeam was developing this technology by using substrates of ceramic and aluminum at a .020″ mil thickness. The UV or ultraviolet wavelength worked best for precision control of the cut array. The critical tolerance of +/- 0.0254mm and smooth aperture walls were made with minimal heat affect. Other laser systems like infrared and fiber proved too hot for this application and CNC routing and Milling were not a good fit for this project due to cracking and stress damage of the substrate.

Contract PCB Assembly: This industry is always in the midst of quick turn with high demand orders. PCB assembly houses do have equipment to depanel or singulate the fully populated boards by means v-scoring, routing or nibling, and sawing. These methods have larger tolerance than laser technology. However, tolerance limitations of +/- 0.127mm to 0.254mm and higher do not fit well for smaller and smaller boards in electronics. These projects need smaller cutting tools as used in laser technology. The beam of laser systems available to cut material like FR4 and Rogers type are about 20um in diameter, which is much smaller than the smallest drill bit in use. Additionally, the laser tolerance can cut at a+/- 0.0762m to 0.1016mm. The process does not add vibration to the soldered components, nor does it add debris. Examples of these types of PCB boards are applied to lidar, medical device systems, defense, aerospace, and consumer electronics.

Laser cut projects are not unique in occurrence, but the projects they support are unique. With continuing ideas for products and advancing technology, laser projects are part of the process that manifests these new ideas to improve our healthcare, improve transportation, and keep consumer goods to the high levels we expect. There are numerous manufacturing methods available to produce precision components, but there are those projects that are a better fit for one technology over the others. When you have a new project, keep in mind these key indicators as a guide to determine if your idea is a good candidate for a laser cutting project.

- Intricate Designs and Fine Details: If your project requires complex shapes, intricate patterns, or small, precise features.

- Variety of Materials: Laser cutting can work with a wide range of materials, including metals, plastics, wood, and composites.

- Material Thickness: Precision parts needing ultra-thin gauges of materials may have only one option and that is laser technology. Thickness between 0.0127mm to 0.254mm often are best done by laser.

- Minimal Material Waste: Laser cutting allows for precise cutting, minimizing material waste.

- Quick Turnaround: Laser cutting often has shorter setup times and can produce parts quickly, especially for smaller quantities or prototypes.

- R&D To Production Potential: Laser projects for a prototype or R&D work are often on a short timetable. It is this capacity that gives laser methods an edge. Additionally, as lower volume projects ensue, manufacturers determine the scalability of throughput for higher production volume manufacturing.

- Customization and Flexibility: Laser cutting can accommodate a variety of designs and modifications, making it suitable for projects that require customization or frequent iterations.

- Edge Quality: If you need clean, burr-free edges on your parts, laser cutting can provide a superior finish. Post finishing is available, especially for metal alloy projects.

Manufacturing is in many ways an art form in itself. With so many methods available to produce precision parts, each technology does have its group creators that are able to visualize the concepts and with skill and experience, apply their knowledge. Laser cutting technology is one of those that when the details all come together, the results are fantastic.